- 22

- Sep

Menene matakan lamination na matakan mica?

Binciken kwatankwacin aikace -aikacen katako na mica da laminate fiberlass fiber fiber zane

Ana amfani da katako na Mica da laminate gilashin filastik filastik a rayuwar yau da kullun. A yau, za mu yi nazarin kwatankwacin aikace -aikacen allon mica da laminate fiber fiber fiber zane. Na farko shine allon mica:

Kwamitin mica yana da kyakkyawan ƙarfin lanƙwasa da aikin sarrafawa. Kwamitin mica yana da babban lanƙwasawa da kyakkyawan tauri. Ana iya sarrafa allon mica a cikin siffofi daban -daban ba tare da delamination ba. Kyakkyawan aikin muhalli, allon mica bai ƙunshi asbestos ba, yana da ƙarancin hayaƙi da ƙanshi lokacin zafi, har ma ba shi da hayaƙi da ɗanɗano.

Daga cikin su, katako na mica mai ƙarfi na HP-5 babban kayan farantin mica ne mai ƙarfi. Kwamitin mica har yanzu yana iya riƙe aikin sa na asali a ƙarƙashin yanayin zafi mai zafi. Ana amfani dashi sosai a cikin fannoni masu zuwa:

Kayan aikin gida: baƙin ƙarfe na lantarki, masu busar gashi, masu toaster, masu kera kofi, tanda na microwave, wutar lantarki, da sauransu;

Metallurgical da sinadaran masana’antu: masana’antu mita tanderu, matsakaici mita makera, lantarki baka tanderu, inji gyare -gyaren inji, da dai sauransu a cikin metallurgical masana’antu.

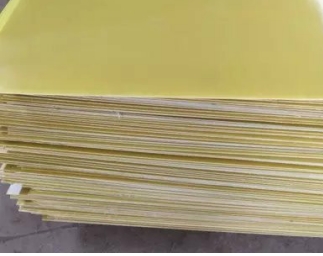

Gilashin filastik filastik laminate: An yi ƙyallen fiber ɗin gilashi ta hanyar dumama da dannawa tare da resin epoxy. Yana da babban aikin injiniya a matsakaicin zafin jiki da tsayayyen aikin lantarki a babban zafin jiki. Ya dace da manyan sassan rufi don injin, kayan lantarki da kayan lantarki, tare da manyan injiniyoyi da kaddarorin dielectric, juriya mai kyau da juriya. Matsayin juriya mai zafi F (digiri 155). Zuwa

Halin da ke tsakanin resin epoxy da wakilin maganin da ake amfani da shi ana aiwatar da shi ta hanyar tarawa kai tsaye ko raunin buɗe polymerization na ƙungiyoyin epoxy a cikin ƙwayar resin, kuma babu ruwa ko wasu samfura marasa ƙarfi da aka saki. Idan aka kwatanta da sinadarin polyester da ba a cika cikawa da reshen phenolic ba, suna nuna raguwar raguwa sosai a lokacin warkarwa. Tsarin warkar da epoxy resin yana da kyawawan kaddarorin inji. Amma aikin gabaɗaya bai yi kyau kamar allon mica ba.

Halayen aikace-aikace

1. Sigogi iri -iri. Dabbobi daban -daban, wakilai masu warkarwa, da tsarin canzawa na iya kusan dacewa da buƙatun aikace -aikace daban -daban akan fom, kuma kewayon na iya kasancewa daga ɗan ƙaramin danko zuwa madaurin daskarewa.

2. Magani mai dacewa. Zaɓi wakilai daban -daban na warkarwa, tsarin resin epoxy kusan ana iya warkewa a cikin yanayin zafin jiki na 0 ~ 180 ℃.

3. Manne mai ƙarfi. Ƙungiyoyin polar hydroxyl na asali da haɗin ether a cikin sarkar kwayoyin resins na epoxy sun sa ya zama mai mannewa ga abubuwa daban -daban. Rushewar resin epoxy yana da rauni yayin da ake warkewa, kuma damuwar cikin da aka samar tana da ƙanƙanta, wanda kuma yana taimakawa haɓaka ƙarfin adhesion.

Musammantawa kauri: 0.5 ~ 100mm

Bayani na al’ada: 1000mm*2000mm

Launi: rawaya, ruwan shuɗi, baki

Taurin laminate gilashin fiber epoxy ya fi na katakon mica, amma bambancin zafin jiki ya ɗan bambanta.