- 17

- Sep

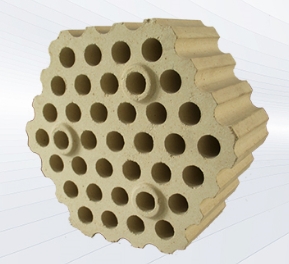

Nnukwu ihe nlele aluminom dị elu maka stovu mgbawa ọkụ

Nnukwu ihe nlele aluminom dị elu maka stovu mgbawa ọkụ

Product advantages: good volume stability, excellent high temperature load creep performance, high density and low porosity.

nkọwa ngwaahịa

High-aluminum checker bricks for hot blast stoves are currently widely recognized and accepted by the world’s ironmaking industry as a heat-carrying heat storage body with many superior thermal characteristics, such as strong heat exchange capacity, large heat storage area, smooth ventilation, and low resistance. The high-aluminum checker brick for hot blast stove is a kind of heat transfer medium, which is mainly used in the middle and upper part of the regenerator of hot blast stove to store heat. In the process of heating cold air into hot air, it plays an extremely important role.

Ngosipụta anụ ahụ na kemịkal

| Ọkwa/Ndepụta | Brik alumina dị elu | Brick nke alumina nke abụọ | Brick alumina dị elu nwere ọkwa atọ | Brick alumina dị oke elu |

| NXZ-75 | NXZ-65 | NXZ-55 | NXZ-80 | |

| AL203 ≧ | 75 | 65 | 55 | 80 |

| Fe203% | 2.5 | 2.5 | 2.6 | 2.0 |

| Nnukwu njupụta g / cm2 | 2.5 | 2.4 | 2.2 | 2.7 |

| Ike mkpakọ na ọnụ ụlọ okpomọkụ MPa> | 70 | 60 | 50 | 80 |

| Ibu Ibu nro nro ° C | 1520 | 1480 | 1420 | 1530 |

| Refractoriness ° C> | 1790 | 1770 | 1770 | 1790 |

| Porosity pụtara% | 24 | 24 | 26 | 22 |

| Ọnụ mgbanwe mgbanwe ahịrị na -adịgide adịgide% | -0.3 | -0.4 | -0.4 | -0.2 |