- 11

- May

How to choose a round steel quenching furnace?

How to choose a round steel quenching furnace?

A. The composition of the round steel quenching furnace:

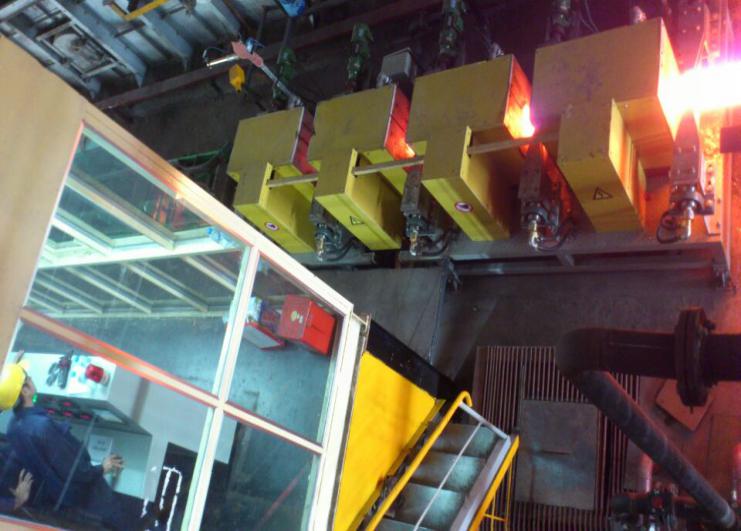

Round steel quenching forno a frequenza intermedia is composed of thyristor intermediate frequency induction heating power supply, Siemens PLC control system, induction heating system, quenching induction system, cooling water spray system, tempering induction system, transmission and conveying system, far infrared temperature measurement system and other configurations.

B. Detailed introduction of round steel quenching furnace:

1. Thyristor medium frequency induction heating power supply:

The complete control system of the thyristor medium frequency induction heating power supply is produced by imported technology, and the frequency is automatically tracked and adjusted by the constant back pressure time inverter control method. The intermediate frequency power supply has reasonable wiring and strict assembly process, and has the advantages of perfect protection system, high power factor, convenient operation and maintenance, and high reliability.

2. Transmission and conveying system of round steel quenching furnace:

It is mainly composed of frequency conversion motor reducer drive, high-strength pressure roller, and idler components. The idler adopts a double-seat supporting steel roller structure. The high temperature resistant insulating material is filled between the steel roller and the inner sleeve, and the inner sleeve is connected with the shaft key. It is not only easy to disassemble, but also prevents surface burns caused by contact with the steel roller during the transmission of the workpiece.

3. Induction heating heat treatment system:

È composto principalmente da più set di sensori, collegamento di barre di rame, divisore d’acqua (ingresso dell’acqua), tubo dell’acqua di ritorno chiuso, telaio in acciaio del canale, giunti dell’acqua a cambio rapido, ecc.