- 01

- Nov

With the help of breathable bricks, briefly talk about the common basic knowledge of refractory materials

With the help of breathable bricks, briefly talk about the common basic knowledge of refractory materials

For steel manufacturers and refractory materials industry, 通気性のあるレンガ are very important and common refractory products; with the help of breathable bricks, this article discusses some basic knowledge of refractory materials from the three aspects of porosity, air permeability, and thermal expansion.

For steel manufacturers and refractory materials industry, breathable bricks are very important and common refractory products; with the help of breathable bricks, this article discusses some basic knowledge of refractory materials from the three aspects of porosity, air permeability, and thermal expansion.

(Picture) Refractory

Porosity of refractory material: the percentage of the volume of pores contained in the refractory material to the total volume. The size of the porosity has a considerable influence on the properties of refractory products, especially physical strength, thermal conductivity, thermal shock resistance and slag resistance. The size of the porosity is closely related to temperature, air pressure, etc. As the temperature rises and the air pressure increases, the porosity will also increase. With the increase of the use temperature, the apparent porosity of the air-permeable bricks for ladle gradually increases, and the volume density decreases.

Air permeability of refractory material: Air permeability refers to the performance of a material to allow gas to pass under a pressure difference. For refractory materials, air permeability is a characteristic that characterizes the ease with which a certain amount of gas can pass through a refractory product under specific conditions. value. For ladle air-permeable bricks, the greater the air permeability, the better, and the smaller the other refractory materials, the better.

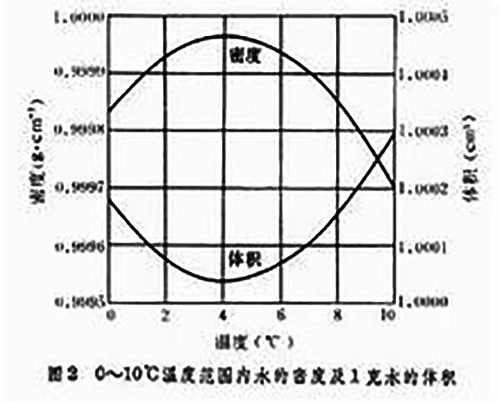

(Picture) Expansion curve

Thermal expansion of refractory materials: With the increase of temperature, the volume or length of refractory materials will increase, which is thermal expansion. The thermal expansion of refractory materials is closely linked to the safe production of steelmaking. In the baking stage of use, if the thermal expansion performance of the air-permeable brick is poor, it will expand and crack and cause damage; in addition, cracks may occur during use, which will affect the smooth progress of steelmaking.

firstfurnace@gmil.com produces a variety of refractory materials, such as breathable bricks, burner bricks, electric furnace covers, etc., which can meet the refining conditions of molten steel refining and can be completed more. Experienced, skilled and professional manufacturers are trustworthy! Luoyang firstfurnace@gmil.com Co., Ltd. has been focusing on the research and development, production and sales of refractory materials such as breathable bricks for 17 years. It is a professional refractory material manufacturer.