- 15

- Feb

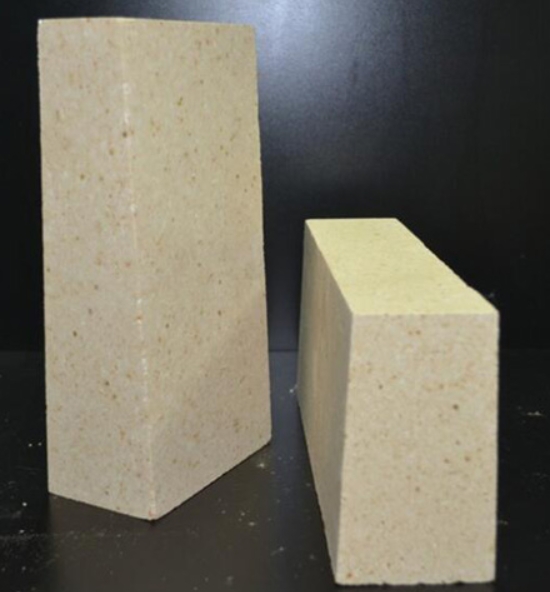

What are the uses of different types of high alumina bricks?

What are the uses of different types of høye aluminiumoksidstein?

Det finnes mange typer av høye aluminiumoksidstein, and they play different purposes in their respective fields. Let’s take a look together below:

Introduction to the use of high alumina bricks:

1. High alumina bricks for general purpose

Raw materials and technology: Generally, high-alumina bricks are made of high-quality bauxite clinker, combined with clay and additives.

Characteristics: The product has the advantages of high refractoriness, good acid and alkali corrosion resistance, high temperature strength, and good thermal shock stability.

Usage: Widely used in thermal equipment in metallurgy, petroleum, chemical, building materials, machinery, processing and other industries.

Ekte kart med høy aluminiumoksid

2. High alumina bricks for blast furnace

Raw materials and technology: High-alumina bricks for blast furnace use high-quality bauxite clinker as the main raw materials, which are formed by high-pressure molding and high-temperature sintering. The main mineral components are mullite and corundum.

Characteristics: The product has excellent high temperature mechanical properties and chemical resistance.

Usage: Used in various parts of blast furnace lining.

3. High alumina bricks for steel-making electric furnace roof

Product features: High alumina bricks for steel-making electric furnace tops are made of selected super-grade bauxite clinker as the main raw material, through high-pressure forming and high-temperature sintering. The main mineral composition is corundum and mullite phase, which has excellent high-temperature mechanical properties and chemical resistance. Especially for non-burned products, the external dimensions are more and the thermal shock stability is better.

4. High alumina bricks for steel drums

Product features: High alumina bricks for steel drums are made of selected bauxite as the main raw material, formed by high-pressure molding and high-temperature sintering. The main mineral composition is corundum and mullite phases. It has good high-temperature mechanical properties and chemical resistance. Corrosion performance.

5. Low creep series high alumina bricks for hot blast stove

Raw materials and technology: Low creep series high alumina bricks for hot blast stoves are made of corundum mullite and Yangquan fine bauxite clinker as the main raw materials, through high pressure forming and high temperature sintering.

Characteristics: The product has a high softening temperature under load, good high temperature creep resistance, and excellent thermal shock resistance.

Use: It is the preferred material for large and medium-sized hot blast stoves.

The above is the introduction of various high alumina bricks. We provide users with high-quality products with excellent raw materials, reasonable prices and complete varieties.