- 18

- Sep

G10 Fiberglass Laminated Sheet

G10 Fiberglass Laminated Sheet

A. Product introduction

Main technical features and applications: stable electrical insulation, good flatness, smooth surface, no pits, thickness tolerance standard, suitable for products with high-performance electronic insulation requirements, such as FPC reinforcement boards, PCB drilling pads, glass Fiber meson, potentiometer carbon film printed glass fiber board, precision star gear (wafer grinding), precision test plate, electrical (electrical) equipment insulation support spacer, insulation backing plate, transformer insulation plate, motor insulation, grinding gear, Electronic switch insulation board, etc.

NEMA is a material standard stipulated by the American Electrical Manufacturers Association. The corresponding IEC standard is EPGC202. There is no domestic standard corresponding to it.

The domestic standard that zui is close to is 3240 epoxy laminated glass cloth board. The corresponding IEC standard of 3240 is EPGC201, and there is only a difference in flame retardancy between EPGC201 and EPGC202. Therefore, it can be simply considered that FR-4 is an improved product of 3240 with enhanced flame retardancy.

FR-4 is also called FR4 epoxy board, and its classification is very wide. The main models are:

G11: Flame retardant grade UL94V0, in dry and wet state, the electrical performance is still very good, it is a good choice for electrical insulation

G10: Flame retardant grade UL94V2, in dry and wet state, the electrical performance is still very good, it is a good choice for electrical insulation

JC833: Flame retardant grade UL94V0, density within 1.8-2.0, widely used in electrical and electronic insulation parts, as well as insulation boards of airplanes, motor cars, transformers, precision cruisers, etc.

JC834: Flame retardant grade UL94V0, density within 1.8-2.0, widely used in electrical and electronic insulation parts, as well as insulation boards of airplanes, motor cars, transformers, precision cruisers, etc.

G10 epoxy board is a plate-shaped insulating material made of glass fiber cloth impregnated with epoxy resin as an adhesive, dried and hot pressed. It has high mechanical properties, water absorption, flame retardancy and heat resistance, and stable dielectric properties after immersion in water. Suitable for products requiring high-performance electronic insulation, such as FPC reinforcement boards, PCB drilling pads, glass fiber mesons, carbon film printed glass fiber boards for potentiometers, precision star gears (wafer grinding), precision test panels, electrical ( Electrical appliances) equipment insulation stay spacers, insulation backing plates, transformer insulation plates, motor insulation parts, grinding gears, electronic switch insulation plates, etc.

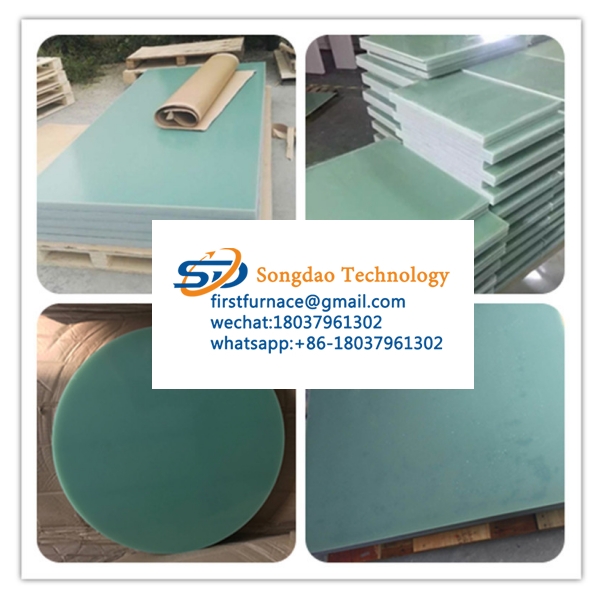

B. Product specifications

Overall board specifications: 1020mm * 1220mm, 1000mm*2000mm, 914*1220mm, 1440*1440mm, 1220mm*2440mm (non-scalar quantities can be customized) Thickness: 0.1mm-350mm

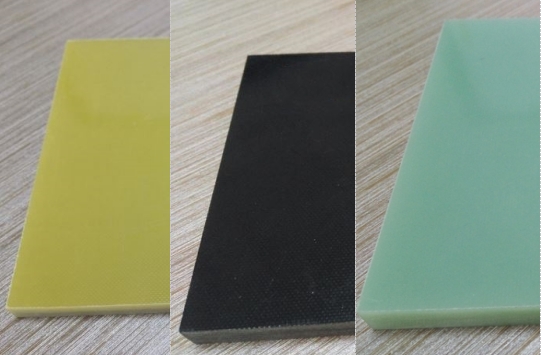

C. Product color

D, product characteristics

D, product characteristics

1. Variety of colors: Compared with 3240 yellow, G10 has white, yellow, aqua and black colors to choose from. And the surface is flat and smooth without bubbles, and the appearance is beautiful.

2. Fire rating: UL94V0, the highest fire rating. Different from the general fire rating, UL94V0 has achieved the effect of fire and flame retardant. It can self-extinguish in a short time after the material passes through the burning state, escorting the safety of life and property.

3. Strong insulation: G10’s natural insulation performance is extremely strong. In the dry and wet state, the electrical performance is still very good, and it is a good choice for electrical insulation.

4. High-quality and practical: G10 still has good adaptability in different environments. Whether it is minus 100°C or high temperature 130°C, it can be applied.

5. Wide range of applications: Because of the excellent performance of G10 and its strong plasticity, it is widely used in electrical and electronic insulation parts, as well as insulation plates for airplanes, motor cars, transformers, precision cruisers and so on.

E. G10- epoxy board and Technical Reference Number

| Performance item | Test Methods | unit | G10 | G10 | |

| Physical properties | density | 2. 0-2. 08 | 2. 0-2. 08 | ||

| colour | yellow | green | |||

| Water absorption | E-24/50+D-24/23 | % | 0. 07-0. 16 | 0. 07-0. 16 | |

| Mechanical behavior | Bending strength | A | MPa | 385-490 | 385-490 |

| Impact strength | A | KJ/m’ | 33 | 33 | |

| Rockwell hardness | A | M | 110 | 110 | |

| Compressive strength | A | MPa | 280-330 | 280-330 | |

| 180-230 | 180-230 | ||||

| Electrical performance | Dielectric strength | 2mm,in oil | KV/ mm | >14 | >14 |

| 2mm,in oil | KV | 40 | 40 | ||

| Unit resistivity | C-96/20/65 | Ω. Cm | ≧1011 | ≧1011 | |

| C-96/20/65+C-96

/40/90 |

Ω. Cm | ≧1010 | ≧1010 | ||

| Surface electrical workers | C-96/20/65 | Ω. | ≧1010 | ≧1010 | |

| C-96/20/65+C-96

/40/90 |

Ω. | ≧1010 | ≧1010 | ||

| Dielectric constant | C-96/20/65 | 4. 0-5. 0 | 4. 0-5. 0 | ||

| C-96/20/65+D-48

/50 |

4. 0-5. 5 | 4. 0-5. 5 | |||

| Medium coefficient

1MHz |

C-96/20/65 | 0. 03-0. 04 | 0. 03-0. 04 | ||

| C-96/20/65+D-48

/50 |

0. 04-0. 05 | 0. 04-0. 05 | |||

| Arc resistance | C-96/20/65 | Sec | 130-140 | 130-140 | |

| Flame retardant | UL94 | A | V-0 | V-0 | |

| Chemical resistance | Acetone resistance | boiled | Min | 30(ok) | 30 (ok) |

| Remark: | Information for reference only, actual indicators in kind for the quasi. | ||||

F. Product display