- 20

- Apr

Injongo yokufudumala kwesithando somlilo

Injongo ye ukufudumeza isithando somlilo

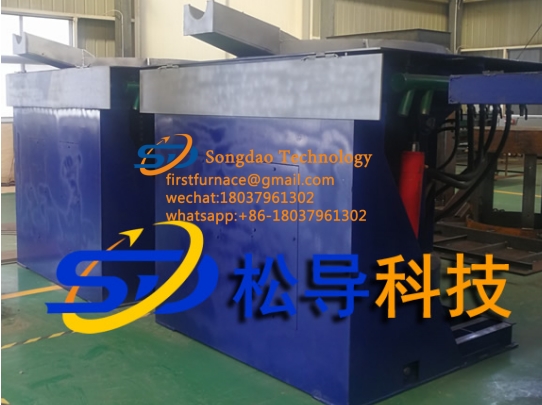

Iziko le-induction zisebenzisa umgaqo wokufudumeza kwe-electromagnetic induction ukufudumeza izinto zokusebenza zetsimbi, kwaye zisetyenziswa ngokubanzi ukwenza isinyithi, ukuphosa, isitampu esishushu, ukuqengqeleka okushushu kunye nokucinywa kwentsimbi kunye nokufudumeza ukufudumeza.

Xa i-furnace induction itshisa i-workpiece, igalelo lomthombo wokushisa wangaphandle liya kubangela ukuba utshintsho lwemo yangaphakathi yamandla engenanto. Njengoko iqondo lokushisa linyuka, amandla e-kinetic yee-athomu ayanda, kwaye ithuba lokushiya indawo yalo yokulinganisa liyanda. Xa kuthelekiswa nobushushu obuqhelekileyo, ukuchithwa kulula Ukuhamba, ukutyibilika kulula, kwaye ukuchasana kwe-deformation kuyancipha; ukongezelela, ukuhamba kwee-athomu eziphezulu zokushisa kunyuka, isantya sokusasazwa sikhawuleza, ukubuyisela kunye nokuhlaziywa kwakhona kulula, kwaye ukubunjwa kwesinyithi kuphuculwe; Ukongeza, ukuhamba kwee-athomu kuyanda kwiqondo lokushisa eliphezulu, kwaye isantya sokusasazwa siyakhawuleza. , kulula ukubuyisela kunye nokuhlaziya kwakhona, kwaye iplastiki yentsimbi iphuculwe; xa izinto ezinokuguqulwa kwe-allotropic zifudumala, kukho iinkqubo ezifana nokuguqulwa kwesigaba, i-recrystallization kunye nokuchithwa kwesigaba kwiqondo elithile lokushisa. Enyanisweni, ukufudumeza kwesithando somlilo kukusombulula iingxaki ezimbini zokubunjwa kunye nokumelana nokuguqulwa kwezinto zokusebenza zetsimbi;

Injongo yokufudumala kwesithando somlilo kukusebenzisa ngokuchanekileyo umthetho we-microscopic evolution ngexesha lenkqubo yokufudumeza i-workpiece yetsimbi, ukuphucula iplastiki yesinyithi, kwaye kwangaxeshanye ufumane i-post-forging structure kunye nokusebenza kakuhle. Ukufudumala kwesithando somlilo kuyikhonkco elibalulekileyo kwi-metal forging, i-casting, i-stamping eshushu, i-hot rolling kunye ne-metal quenching kunye nenkqubo yokufudumala yokufudumala, enefuthe elithe ngqo ekuphuculeni imveliso, ukuqinisekisa umgangatho wokufudumeza kunye nokugcina ukusetyenziswa kwamandla.

Umzekelo, ukuxhathisa deformation yentsimbi stainless 12Cr18Ni9 kubushushu begumbi 640MPa, ukumelana deformation yentsimbi 12Cr18Ni9 kuncitshiswe malunga 120MPa xa ifudunyezwe 800 ℃ kwi induction eziko, kwaye ukumelana deformation kuncitshiswe ukuya malunga 20MPa xa ishushu. 1200℃, engaphantsi ngama-97% kunobushushu begumbi. .