- 08

- Aug

Application fields of all solid-state induction heating equipment

Application fields of all solid-state induction heating equipment

1. Welding: cutting tools, drilling tools, knives, woodworking tools, turning tools, drill bits, brazing reamers, milling cutters, drill bits, saw blades, spectacle frames in the glasses industry, welding of steel pipes and copper pipes, welding of the same kind and different species Welding of metals, compressors, pressure gauges, contact points of relays, composite welding of stainless steel pot bottoms, composite welding of transformer windings of different materials, welding and storage of copper wires (welding of gas filling nozzles, welding of stainless steel dishes, and kitchen utensils).

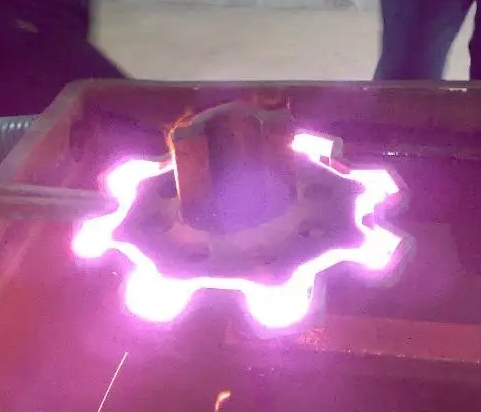

2. Heat treatment: quenching and annealing of mechanical metal parts (surface, inner hole, part, whole) such as gears, machine tool guide rails, hardware tools, pneumatic tools, power tools, hydraulic parts, ductile iron, automobile and motorcycle parts, internal parts, etc., stainless steel Pot products stretch.

3. Diathermy forming: standard parts, fasteners, large workpieces, small hardware, straight shank twist drills, overall and partial heat penetration and hot upsetting and hot rolling of twist drills, round steel with a diameter of less than 100mm, and metal materials Heating and annealing for stretching, molding, embossing, pipe bending, head smashing, steel wire (iron wire) heating nailing, stainless steel products annealing, stretching, expanding, thermal expansion, etc.

4. Other heating fields: heating lamination of aluminum-plastic pipes, steel-plastic pipes, cables and wires, metal preheating and plastic wrapping, semiconductor single crystal growth, heat-fitting, bottle-mouth heat-sealing, toothpaste skin heat-sealing, powder coating, Aluminum foil seals for metal implantation in plastic, food, beverage, and pharmaceutical industries.