- 17

- Sep

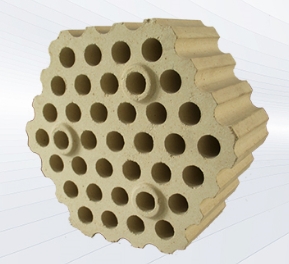

High aluminum checker brick for hot blast stove

High aluminum checker brick for hot blast stove

Product advantages: good volume stability, excellent high temperature load creep performance, high density and low porosity.

product description

High-aluminum checker bricks for hot blast stoves are currently widely recognized and accepted by the world’s ironmaking industry as a heat-carrying heat storage body with many superior thermal characteristics, such as strong heat exchange capacity, large heat storage area, smooth ventilation, and low resistance. The high-aluminum checker brick for hot blast stove is a kind of heat transfer medium, which is mainly used in the middle and upper part of the regenerator of hot blast stove to store heat. In the process of heating cold air into hot air, it plays an extremely important role.

Physical and chemical indicators

| Rank/Index | High alumina brick | Secondary high alumina brick | Three-level high alumina brick | Super high alumina brick |

| LZ-75 | LZ-65 | LZ-55 | LZ-80 | |

| AL203 ≧ | 75 | 65 | 55 | 80 |

| Fe203% < | 2.5 | 2.5 | 2.6 | 2.0 |

| Bulk density g/cm2 | 2.5 | 2.4 | 2.2 | 2.7 |

| Compressive strength at room temperature MPa> | 70 | 60 | 50 | 80 |

| Load softening temperature °C | 1520 | 1480 | 1420 | 1530 |

| Refractoriness °C> | 1790 | 1770 | 1770 | 1790 |

| Apparent porosity% < | 24 | 24 | 26 | 22 |

| Heating permanent line change rate% | -0.3 | -0.4 | -0.4 | -0.2 |