- 25

- Aug

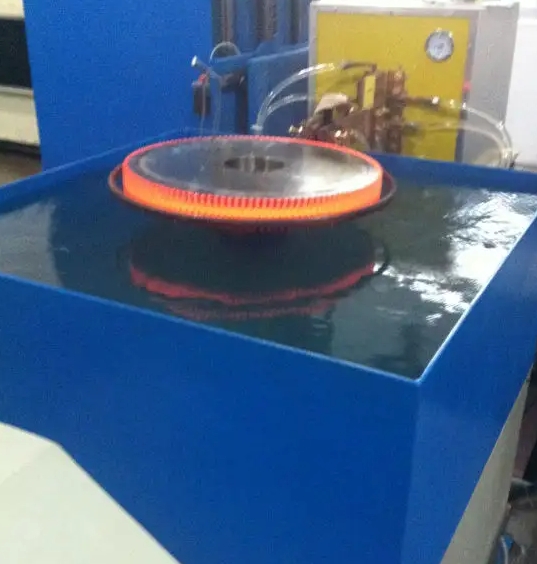

Repair and maintenance of high frequency quenching machine tools

Repair and maintenance of yüksək tezlikli söndürmə dəzgahları

When maintaining the high frequency quenching machine tool, the first thing we need to do is to operate the standard. All machines have relevant strict operation manuals, because the operation steps will not only affect the operation efficiency of the machine, but also affect the service life of the machine. For example, when using quenching equipment, when we need to stop the machine, we should Turn off all parts of the machine step by step instead of directly unplugging the quenching equipment. Although unplugging the quenching equipment directly will power off faster, such illegal operations will easily lead to damage to some parts of the machine tool or even appear. The phenomenon of premature aging of the line.

In addition to paying attention to the operating specifications of the quenching equipment, when maintaining the quenching machine tool, the machine tool should be lubricated regularly. The reason why the newly purchased machine tool can maintain good operating efficiency is largely because the various parts of the machine tool run fast, but as the machine is used for a long time, the lubrication of the machine parts in various parts decreases, and the performance of the machine will also decrease. Therefore, regularly lubricating the machine can maintain the performance of the machine and prolong its service life.