- 29

- Nov

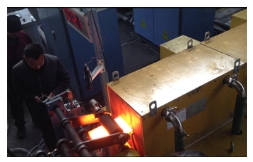

Daily maintenance content of intermediate frequency induction heating equipment (to be performed every day)

Daily maintenance content of intermediate frequency induction heating equipment (to be performed every day)

(1) Thoroughly remove the oxidized slag accumulated in the intermediate frequency induction furnace, and carefully check whether the insulation lining is cracked or damaged. If the problem is found, fix it in time.

(2) Check the waterway to ensure that the waterway is unobstructed, the backwater is sufficient, there is no leakage, and the inlet water temperature is not greater than 35 degrees Celsius. If the problem is found, deal with it in time.

(3) Observe whether the varistor, protection resistor and capacitor in the intermediate frequency power supply cabinet are abnormal in appearance, whether the fastening bolts are loosened, whether the solder joints are desoldered or weakly welded, and whether the intermediate frequency capacitor electrolyte leaks. If any problems are found, notify the maintenance personnel in time.