- 14

- Oct

Take you to learn the knowledge of epoxy glass fiber board

Take you to learn the knowledge of epoxy glass fiber board

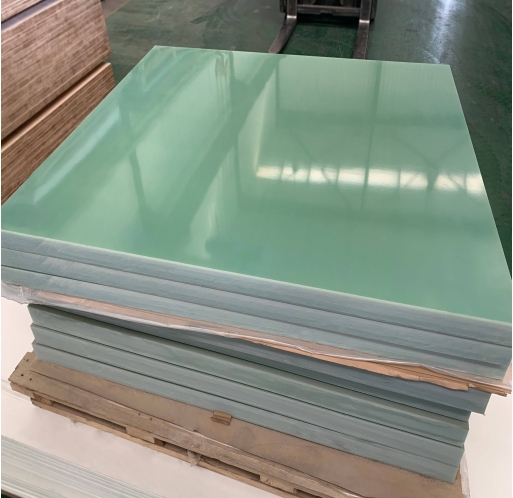

With the progress and development of the times and the popularization of electric power public base construction, epoxy fiberglass board is more and more widely used in the society. Many people do not know the function and use of epoxy fiberglass board. This time, you will be Under the leadership of Tatsu Insulation, learn the epoxy fiberglass board you don’t know.

Aluminum base plate is the most widely used circuit board, it has good heat dissipation and is the cheapest among the thermally conductive metals. The aluminum substrate is divided into three layers, the top layer is the circuit board layer, and the wiring layout is used. The middle part is a heat-conducting and heat-insulating layer, and the bottom part is a heat-dissipating aluminum base layer. The aluminum substrate has a good cost performance, making it popular in LED lamp manufacturing.

The important parts of the light bulb are the circuit board, the LED chip and the driving power supply. Commonly used circuit boards are divided into two types: aluminum substrates and epoxy fiberglass boards. The price of epoxy glass fiber board is much cheaper than aluminum substrate. According to different materials and manufacturing processes, it can be divided into double-sided copper foil epoxy glass fiber board, perforated copper foil glass brazing board and single-sided copper foil epoxy glass fiber board. The prices of epoxy glass fiberboards produced by different materials and processes are also different. Epoxy glass fiber board LED bulbs do not dissipate heat as well as aluminum substrate LED bulbs.

In addition, the materials of the insulating layer and the heat-conducting layer can also save costs. The best thermal conductive material is special ceramic polymer, and the price is of course the most expensive. Generally, epoxy resin and glass cloth are used as thermal conductive materials for low-cost aluminum substrates.

Finally, there is a difference between the copper plate and the aluminum plate on the aluminum base. The aluminum substrate made of copper plate has a very good heat dissipation effect, but the cost will increase a lot. In order to ensure cost performance, LED lamp manufacturers usually choose aluminum plates to make aluminum substrates. The LED emergency light bulbs produced by the half-moon lighting are of high quality. After passing the layer-by-layer test, strictly control the quality, prevent shoddy manufacturing, and prevent the use of shoddy epoxy glass fiber board to replace the aluminum substrate. Consumers and distributors are asked to keep their eyes open and do not buy because of the cheap inferior products on the market.