- 29

- Oct

Purchasing refractory bricks requires cooperation with refractory brick manufacturers

Purchasing refractory bricks requires cooperation with refractory brick manufacturers

The demand side of refractory bricks is more willing to cooperate with strong refractory brick manufacturers. On the one hand, it is related to the traceability of the quality of use, and on the other hand, it is also related to whether the ultra-high procurement cost can be guaranteed. How can honest and reliable refractory brick manufacturers ensure that the cost-effectiveness of cooperative procurement is fully realized?

1. Factory direct sales to avoid other costs

Refractory brick manufacturers conduct face-to-face sales through factory direct sales. On the one hand, they do not need to pay any intermediary fees. On the other hand, the related publicity costs are greatly reduced. They are truly introduced on the premise of cooperating with customers. On the basis of further optimizing other additional costs, refractory brick manufacturers can obviously provide more affordable prices.

2. Mass production reduces costs

Refractory brick manufacturers are in mass production, which makes the purchase of raw materials and production-related costs have been better reduced, and provides practical value and practical value for optimizing the cost of production preparation. On the basis of mass production, more demanding partners can obtain products with lower prices, and truly realize the business philosophy of increasing revenue and reducing expenditure.

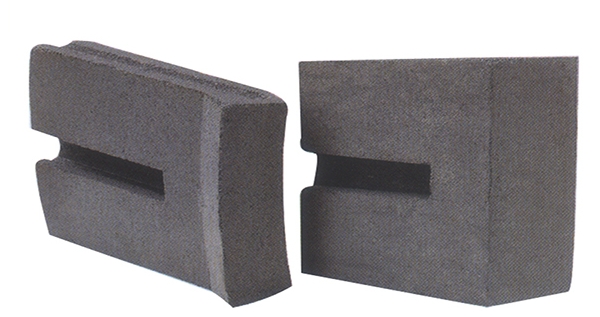

3. Diversified categories and comprehensive quality assurance

Refractory brick manufacturers pay attention to the realization of optimized production, with a wide range of varieties and high quality requirements, which well meet the requirements of actual use. It is built on the premise of higher use value, and it also provides the necessary elements for comprehensive cost-effective accounting.