- 16

- Jun

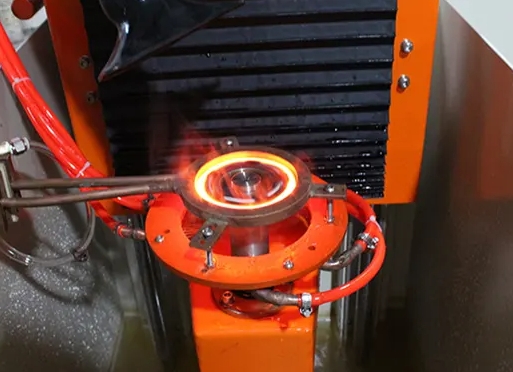

Quenching machine tool manufacturers share the advantages of induction heating equipment

Quenching machine tool manufacturers share the advantages of induction heating equipment

1. There is no need for overall heating, the deformation of the workpiece is small, and the power consumption is small.

2. The quenching machine tool manufacturer said that this method is pollution-free.

3. The heating speed is fast, and the surface oxidation and decarburization of the workpiece is lighter.

4. The surface hardened layer can be adjusted according to the needs, which is easy to control.

5. The quenching machine tool manufacturer stated that the heating equipment can be installed on the machining production line, which is easy to realize mechanization and automation, easy to manage, and can reduce transportation, save manpower, and improve production efficiency.

6. The martensite structure of the hardened layer is finer, and the hardness, strength and toughness are higher.

7. The quenching machine tool manufacturer also mentioned that after surface quenching, the surface of the workpiece has a large compressive internal stress, and the workpiece has a high resistance to fatigue and fracture.