- 03

- Oct

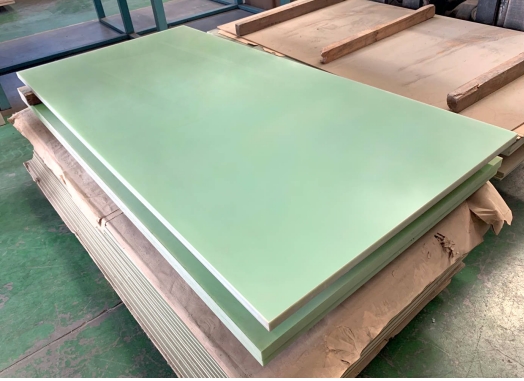

Epoxy fiberglass cloth laminate

Epoxy fiberglass cloth laminate

Epoxy glass cloth laminate is a non-woven fabric made of alkali-free glass fiber through shearing, sedimentation, bonding, baking and other processes. It is called glass fiber mat or non-woven fabric. Started trial production. Its structure is evacuated, has good permeability, and is isotropic. Compared with glass cloth, it has simple process and low price. The non-alkali chopped glass fiber mat is used as a reinforcing material and is impregnated with epoxy adhesive to make epoxy glass mat laminates made of prepreg. It has excellent mechanical properties and processability. It is often used to make supports and Used as a fixing part for fixing the winding end of a large turbo-generator. It overcomes the creepage phenomenon that is easy to occur with metal fixing parts, thereby greatly improving the reliability of the operation of large generators.

Epoxy glass fiber cloth laminate has the following properties: good electrical performance under high humidity environment, good mechanical performance under medium temperature, flame retardancy (FR series), voltage resistance, stable product quality, etc. It can be processed into various parts by lathe processing, punching, trimming, drilling, sandblasting, grinding, sawing and milling. Epoxy glass fiber cloth laminates are widely used in motors, electrical equipment, circuit breakers, switch cabinets, transformers, DC motors, AC contactors, explosion-proof electrical appliances, cruise ships, low-voltage electrical insulation partitions, etc., electrical, electronic, and automotive industries , Medical and other fields.