- 21

- Mar

Kulatá ocelová indukční topná pec

Kulatá ocelová indukční topná pec

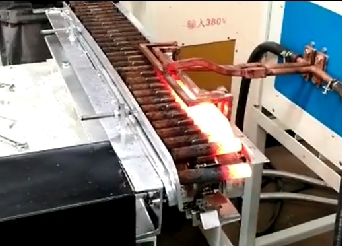

Round steel induction furnaces are often used for heating forging of round bars and sheets to improve metal thermoplasticity. The metal heating workpiece is placed in the induction coil of the alternating magnetic field. Since the induction directly acts on the workpiece itself to generate eddy current and heat, the round steel heating device has short heating time, convenient temperature control, guaranteed heating quality, improved working conditions, and easy integration. produce. Therefore, it has more and more applications.

Summary of technical parameters of round steel induction heating furnace

| Within 1000KW round induction furnace power technical parameters Summary | |||||||

| Rated power(KW ) | Rated frequency (HZ) | Transformer capacity (KVA) | Secondary voltage (V) | Number of commutating pulses | Sensor voltage(V) | Power consumption (KW.h/t) | Round roddiameter ( mm ) |

| 80 | 1000 8000 ~ | 100 | 380v | 6 pulzní | 800 | 450 | Φ 6-35 |

| 100 | 1000 8000 ~ | 160 | 380v | 6 pulzní | 800 | 450 | Φ 25-40 |

| 120 | 1000 8000 ~ | 200 | 380v | 6 pulzní | 800 | 450 | Φ 30-50 |

| 160 | 1000 8000 ~ | 250 | 380v | 6 pulzní | 800 | 450 | Φ 40-60 |

| 200 | 1000 8000 ~ | 315 | 380v | 6 pulzní | 800 | 450 | Φ 40-60 |

| 250 | 1000 8000 ~ | 400 | 380v | 6 pulzní | 800 | 450 | Φ 60-80 |

| 350 | 1000 8000 ~ | 500 | 380v | 6 pulzní | 800 | 450 | Φ 80-120 |

| 400 | 500 8000 ~ | 500 | 380v | 6 pulzní | 800 | 450 | Φ 80-120 |

| 500 | 500 8000 ~ | 630 | 380v | 6 pulzní | 800 | 450 | Φ 120-150 |

| 1000 | 500 1000 ~ | 1250 | 660V-380V | 12 Pulse | 1200 / (800) | 380 | Φ 150-250 |

| 1500 | 500 1000 ~ | 1600 | Φ 660V-380V | 12 Pulse | 1200 / (800) | 370 | Φ 250-400 |

| 2000 | 500 1000 ~ | 2200 | Φ 660V-380V | 12 Pulse | 1200 / (800) | 360 | Φ 400-800 |

Round steel induction heating furnace PLC intelligent control system :

1, the user needs to provide a touch screen or a remote control console

2 , man-machine interface, easy to operate

3 , real-time adjustment of equipment operating parameters

4 , real-time control of the heating process, and has a recording function

5 , different international language switching

Main features of round steel induction heating furnace :

1. It is used for heating various round steels such as carbon steel and iron;

2 , medium frequency and super audio heating round steel, more heated, more uniform and faster;

3 , round steel induction heating furnace small size, easy to move, can be used with any forging and rolling equipment;

4, an induction heating oven round bar is heated to a desired temperature in a very short period of time, greatly reducing the oxidation of the metal, both time and material but also improves the quality of the forging;

5 , automatic feeding, automatic feeding, automatic production capacity;

6. The advantages of round steel induction heating furnace for power saving, environmental protection, cost reduction and manpower expenditure;

7. It is convenient to replace the sensor to meet the different requirements of the overall heating or end heating of the round steel.