- 10

- May

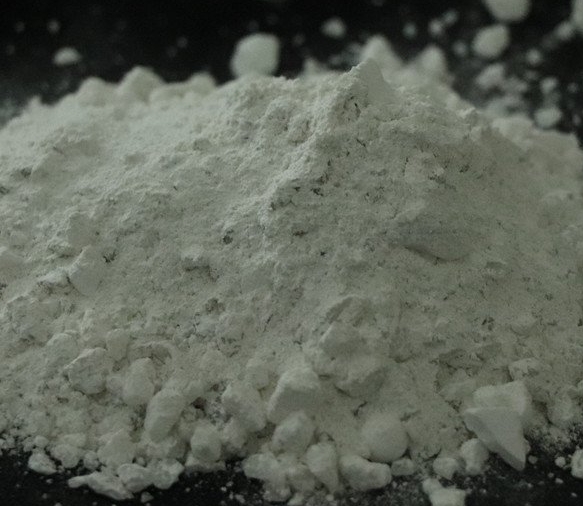

Matters needing attention in the knotting process of induction furnace (ramming material)

Matters needing attention in the knotting process of induction furnace (ramming material)

There are many steps in the whole process of induction furnace (ramming material), and knotting is some of the more important processes. And the process of knotting can also affect the service life of the furnace.

Luoyang Songdao interprets what matters should be paid attention to in the knotting process of furnace lining material (ramming material) to ensure that it does not affect the service life of the furnace?

1. Standardizujte standardní provozní postup, ale kromě toho existuje mnoho opatření v procesu zauzlování pěchovacího materiálu.

For example, before tying the knot, to ensure the power supply and the improvement of the water supply system, it is also necessary to make preparations in advance through the staff of each project. Of course, it also includes that staff are not allowed to bring inflammable and explosive materials into the work site, including mobile phones, keys and other items.

2. Adding sand in the process of adding the induction furnace (ramming material) is a process with strict requirements. For example, the sand must be added at one time, and should not be added in batches. Of course, when adding sand, ensure that the sand is spread on the The bottom of the furnace should not be piled up in a pile, otherwise the particle size of the sand will be separated.

3. Special reminder for induction furnace (ramming material): When tying knots, it should be operated according to the method of shaking first and then vibrating. And pay attention to the method to ensure that the process of operation should be light and then heavy. And the rocker should be inserted to the bottom at one time, and every time the stick is inserted, it should be shaken eight to ten times.

4. After the bottom of the furnace is finished, make sure that it can be put into the dry pot stably. Only in this way can we ensure that the forming is relatively standard, generally it will be a standard annular triangular ring. Of course, there are many steps that need to be paid attention to in the whole knotting process. And every step cannot be ignored.