- 31

- Jan

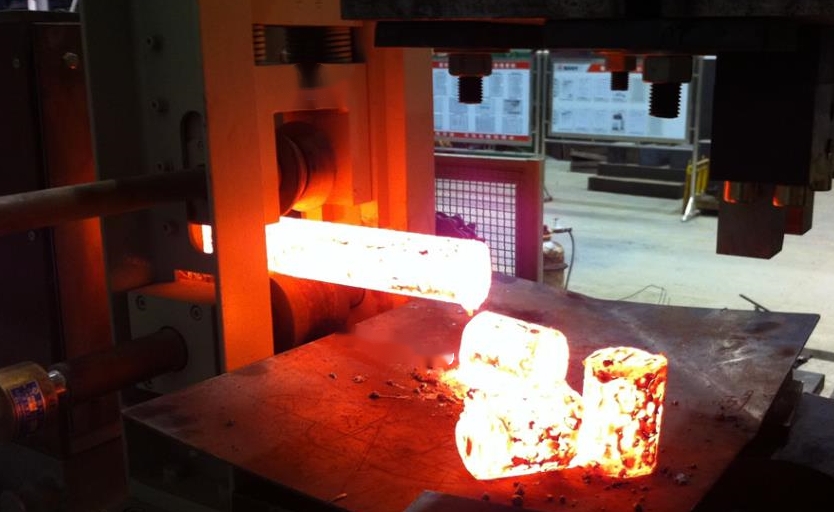

Round steel heating furnace

The round steel heating furnace adopts the electromagnetic heating principle and is equipped with Siemens PLC programming control system to realize the automatic control of the whole process of round steel heating and forging. It has the advantages of reliability and durability, high cost performance, simple operation, energy saving and environmental protection.

The working principle of the round steel heating furnace:

The round steel is placed in the inductor coil of the round steel heating furnace. The inductor is generally a rectangular copper tube spiral coil with an intermediate frequency alternating current (100-8000Hz) inputted by a thyristor variable frequency. The intermediate frequency current generates an alternating magnetic field in the inductor, which will An induced current of the same frequency is generated inside the round steel, which is the generation of eddy current. This eddy current flows inside the round steel to generate heat, so that the round steel itself heats up to achieve the heating effect.

Round steel heating furnace Mechanical system working process:

The mechanical action of the whole set of round steel heating furnace adopts PLC timing control, only need to manually place the round steel in the storage rack, and the rest of the actions are automatically completed by the system under the control of PLC.

Material storage platform→lifting conveying and feeding mechanism→cylinder feeding system→induction heating system→infrared temperature measuring device→quick discharge device→extruder or forging machine

Round steel heating furnace PLC control:

The PLC control system of the round steel heating furnace can realize real-time recording, archiving, query, printing and other functions of the round steel heating production data (including real-time display of production data, production efficiency, workpiece temperature and power supply operating parameters, etc.) The temperature measurement sets the heating temperature of the workpiece, the round steel heating furnace automatically adjusts the power supply to form a temperature closed-loop control, automatically records and analyzes the parameter changes, automatically predicts faults and alarms, remote centralized control, and automatically generates various reports to realize the traceability of the production process. sex.