- 07

- Feb

What are the types of heat treatment and quenching processes? (two)

What are the types of heat treatment and quenching processes? (two)

(4) Pre-cooling and quenching

After quenching and heating, the workpiece is not immediately immersed in the cooling medium, but is first cooled in the air for a short time, and when the workpiece drops to a certain temperature, it is immersed in the cooling medium. This quenching method is called pre-cooling quenching or delayed quenching. .

The key to pre-cooling and quenching is to control the pre-cooling time. Short pre-cooling time is poor; long time may reduce the quenching hardness of the workpiece (non-martensitic transformation occurs). Due to the different materials of workpieces, different shapes and sizes, and also affected by the release temperature and ambient temperature, it is difficult to accurately calculate the pre-cooling time, which mainly depends on the operator’s technology and experience.

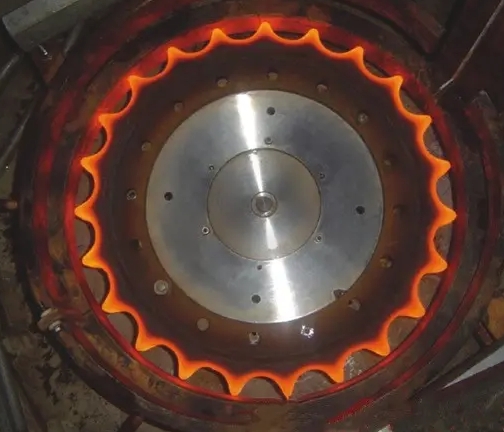

(5) Local quenching

For some workpieces, as long as a certain part has high hardness, other parts have no hardness requirements or require lower hardness. In this case, the local quenching method can generally be used, that is, a method of quenching only a certain part of the workpiece. There are two main forms of local quenching, local heating and local cooling and overall heating and local cooling. The former is mainly suitable for workpieces heated by salt bath furnaces, while the latter can be used in box furnaces and salt bath furnaces.

(6) Cold treatment

Cold treatment is a post-quenching operation in which the quenched steel continues to be cooled to a temperature below room temperature, so that the retained austenite that has not been transformed at room temperature continues to be transformed into martensite.