- 17

- Feb

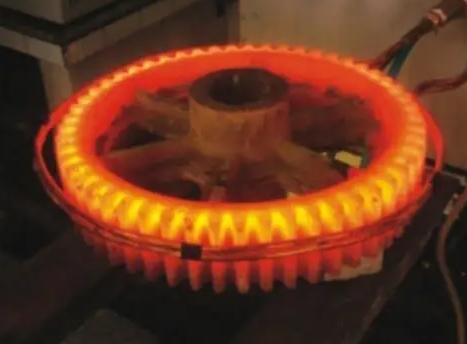

Talk about the daily maintenance method of high frequency quenching machine

Talk about the daily maintenance method of high frequency quenching machine

1. Regular inspection device: Regularly check the contact between the screws and fasteners of various components of the high-frequency quenching machine. If looseness is found, it should be modified and replaced in time to avoid serious consequences.

2. Regularly check whether the wiring is in good condition: carefully check the contact condition of the induction coil of the high-frequency quenching machine. If there is oxide scale, it should be cleaned in time, cracks should be replaced in time, and problems should be found in time to repair the high-frequency quenching machine.

3. Clean up the dirt of the power cabinet: After a period of use, the dust will adhere to the surface of the components, and it should be cleaned in time to prevent the failure of the high-frequency quenching machine.

- Regularly check the water pipe head: due to the different water quality used in various regions, regularly check whether the internal equipment of the high-frequency quenching machine pipe head is dirty. If it is not cleaned for a long time, it will affect the cooling effect and the use time of the water pipe. The phenomenon of aging will occur.