- 31

- Mar

Service life of quenching sensor

Service life of quenching sensor

The service life of sensors can be roughly divided into three types: long-term type (for mass production), medium-term type (for mass and mass production) and short-term type (for small-scale production).

1. The first type

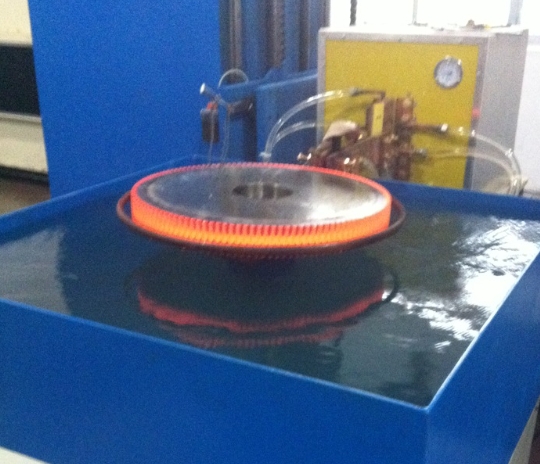

It requires high strength, long life, and high precision, which also brings high cost. The modern manufacturing method of this kind of inductor is processed by CNC machine tools with the whole oxygen-free copper, and its conductive layer has absolutely no weld seam. It is processed from a block of copper with good rigidity. In addition to durability, the manufacturing requirements have good consistency, that is, spare parts are randomly replaced, and qualified products can be produced without adjusting process parameters. Silver brazing is also used for the cover plate of the water chamber, but this part is not a current path. This kind of sensor brazing process is also special, and multiple brazing points are often completed at one time. This kind of inductor has the longest service life, compared with welding inductors, its life is a 1 to 5 figure. This is a crank journal opening and closing sensor machined from integral copper.

2. The second type

The effective circle is finished and welded. This kind of sensor is suitable for mass production and mass production. The precision of the effective circle is high. The whole set of sensors is welded by the mold and inspected by the inspection fixture to ensure the manufacturing accuracy and water flow. It is currently the most commonly used manufacturing Method, due to brazing technology and other reasons, its service life is lower than the first one, and the consistency of the inductor is also slightly lower than the first one. The brazing of the inductor develops from the surfacing type to the capillary infiltration type, and the structure develops from the butt joint To the falcon head interface, it has a great impact on the strength of the sensor. It is recommended to avoid the welding joint of the conductive path, which solves the problems caused by the welding joint from the root.

3. The third type

Molded type, the effective circle is made of copper tube wound on the mandrel, there is a weld in the conductive path, the contact plate is connected with the conductive tube and the plate by brazing, the verticality of the reference plane of the effective circle and the contact plate, and the tolerance of the center line Both are greater than a certain value. After the sensor is installed on the quenching machine tool, its reference plane should be adjusted to be perpendicular to the center line of the machine tool and consistent with the center of the thimble of the quenching machine tool. This kind of sensor is easy to manufacture, low in price, and suitable for small-scale production and research. Its consistency is very low, and its service life is also low, but it also has a large number of user needs.