- 25

- Sep

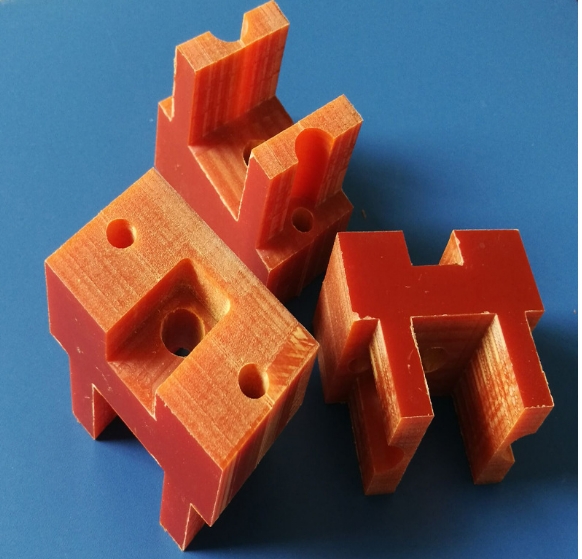

The performance characteristics of the insulating material processing center are summarized as follows

The performance characteristics of the insulating material processing center are summarized as follows

1. Insulation material processing center adopts domestic high-power spindle motor; guide rail: 25 mm linear guide rail

2.x.y-axis transmission: high-precision rack and pinion transmission, fast running speed; z-axis transmission: high-precision ball screw transmission, low East China coefficient, low friction, smooth and fast operation

3. The work surface of the insulating material processing center: six partition vacuum adsorption table surface

4. The insulating material processing center adopts the servo motor produced in Japan; the standard power supply is 220v/50hz or 60hz

5. Compatible with cad/cam and other software

6. The industrial design standard of this machine tool is all-steel structure. The bed has undergone finite element analysis (FEA) and design, and all the bed components have been stress-eliminated before processing. Provide a rigid and stable processing platform for the machine tool.

7. The insulating material processing center adopts a fully automatic lubrication system, which should adapt to the needs of all-weather processing.

8. The main components of this insulating material processing center are all branded, such as the Yaskawa AC servo drive system in Japan, and the automatic tool change spindle imported from Italy.

9. The vacuum adsorption table is divided into six processing areas, which can be processed in a single area or at the same time. The clamping is convenient and fast, and the clamping of large-area plates can be realized at one time to improve the processing efficiency.

The scope of application of the insulating material processing center

Insulation material processing center is used in woodworking, plastics, insulation materials, insulation parts and non-ferrous metal industries, etc.