- 24

- Feb

What is the relationship between mid and high frequency? I can’t even read this article!

What is the relationship between mid and high frequency? I can’t even read this article!

First of all, induction hardening is divided into medium frequency quenching equipment and high frequency quenching equipment. To understand the difference between the two is very important for our equipment selection and process selection. Here is a list of information for everyone.

The obvious difference between medium and high frequency quenching equipment lies in five differences:

The working frequency range is different: the general working frequency of intermediate frequency quenching is 1K-10K; the working frequency of high frequency quenching is 100K-500K.

The oscillation frequency is different: the oscillation frequency of the medium frequency quenching equipment is generally 0.5-20KHZ, and the oscillation frequency of the high frequency quenching equipment is generally 20-80KHZ. The quenching layer is different: the intermediate frequency quenching layer is deeper, more than 3mm; the high frequency quenching layer is shallower, 1-3mm.

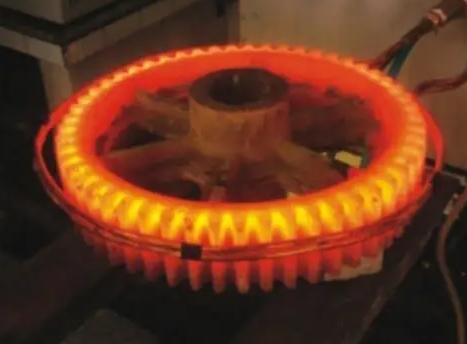

Different applications: medium frequency quenching equipment is suitable for parts that are subject to torsion and pressure loads, such as crankshafts, large gears, grinding machine spindles, etc.; high frequency quenching equipment is suitable for parts that work under friction conditions.

Different effects: different frequencies can achieve different effects. The higher the frequency, the stronger the effect, and the shallower the depth of the induced current flowing into the workpiece; therefore, the workpiece frequency of the intermediate frequency quenching equipment is lower, and the current penetration depth is also Deep, can be used for warm forging or smelting process; high-frequency quenching equipment can be used to complete surface quenching or welding.

The above is the difference between high frequency and intermediate frequency. You must choose the equipment you need according to your own quenched parts. If you don’t understand, you can ask me!