- 06

- Feb

Induktiolämmitysuunin pölynpoistolaitteiden rakenteelliset ominaisuudet

Induktiolämmitysuunin pölynpoistolaitteiden rakenteelliset ominaisuudet

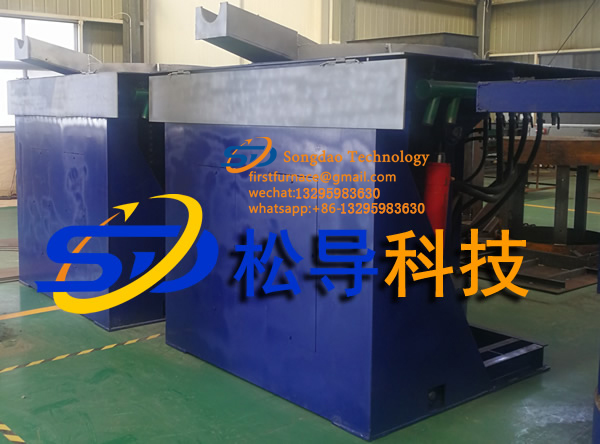

Savukaasujen keräysjärjestelmä induktiokuumennusuuni consists of a low-position mobile dust hood, feeding equipment, tapping equipment and dust removal equipment. The low-position mobile dust hood completely covers the operation channel and the tapping pit, so that the training and production process of the induction heating furnace is all carried out in the low-position mobile dust hood, which realizes the effective capture of the flue gas in the whole process.

When feeding, the feeding equipment is used for feeding, and the material is filled several times according to the production demand, which solves the problem that the flue gas is difficult to capture during feeding. In the ladle, the tapping process is completed in the fume hood, which overcomes the partial leakage of the flue gas when tapping the part of the dust hood.

The advantage of the induction heating furnace dust collector is that the dust removal power is high, generally above 99%, the dust concentration in the outlet gas of the dust collector is within a few 10mg/m3, and it has a high classification power for fine dust with submicron particle size. Induction heating furnace The bag filter can handle a wide range of air volume. The small one is only a few m3 per minute, and the large one can reach tens of thousands of m3 per minute. It can be used for flue gas dust removal in industrial furnaces and kilns to reduce the emission of air pollutants. The dust collector has a simple structure and is easy to maintain. Easy to operate. Under the premise of ensuring the same high dust removal power, the cost is lower than that of the electrostatic precipitator. The induction heating furnace bag filter uses glass fiber, PTFE, P84 and other high temperature resistant filter materials, which can be used in high temperature conditions above 200 ℃ The bag filter of induction heating furnace is not sensitive to the characteristics of dust, and is not affected by dust and resistance.

The high temperature resistant bag filter of the induction heating furnace adopts an electrical control system. The low-position mobile dust hood, the feeding car and the ladle car all have on-site wireless remote control devices, which are fast and convenient to operate and have strong practicability. The monitoring system of the dust removal system is responsible for the normal operation of the dust collector. The required active control tasks of cleaning and unloading operations and safety maintenance of dust collectors use PLC programmable controllers, which have higher reliability, flexibility and compatibility.