- 12

- Apr

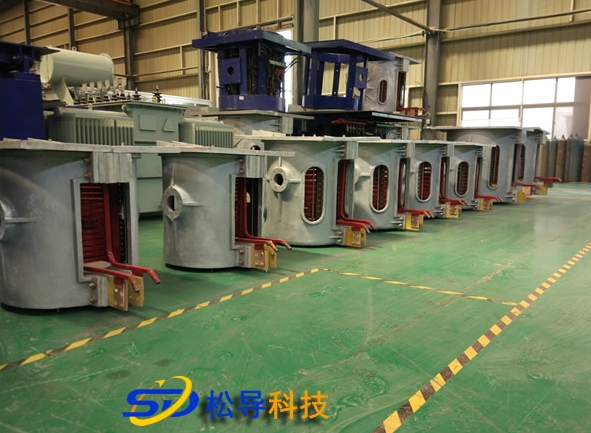

Inspection of Induction Melting Furnace Repairing Fixed Capacitors

Tarkastus Induktio-sulatusuuni Repairing Fixed Capacitors

(1) Detect small capacitors below 10pF. Because the capacity of the fixed capacitor below 10pF is too small, when measuring with a multimeter, it can only be qualitatively checked for leakage, internal short circuit or breakdown. When measuring, you can choose a multimeter R×10k block, and use two meter pens to connect the two pins of the capacitor randomly, and the resistance should be infinite. If the measured resistance value (the pointer swings to the right) is zero, it means that the capacitor is damaged by leakage or an internal shock.

(2) Detect whether the 10pF~1000uF fixed capacitor is charging, and then judge its quality, the multimeter selects Rx1k gear. If the B value of the two triodes is more than 100, and the penetration current should be small, 3Dc6 and other types of triodes can be used to form a composite tube. The red and black test leads of the multimeter are respectively connected to the emitter e and collector c of the composite tube. Due to the amplification effect of the composite transistor, the charging and discharging and power process of the capacitor under test are amplified, so that the pointer swing of the multimeter is increased. So as to facilitate observation. It should be noted that during the test operation, especially when measuring capacitors with smaller capacitance, the pin contact points of the capacitor under test must be repeatedly exchanged, so that the movement of the pointer of the multimeter can be clearly seen. ,

(3) For fixed capacitors above 1000uF, the Rx10k file of the multimeter can be used to directly test whether the capacitor has the charging process, and whether there is internal short circuit or leakage, and the capacity of the capacitor can be estimated according to the magnitude of the pointer swing to the right.