- 19

- Sep

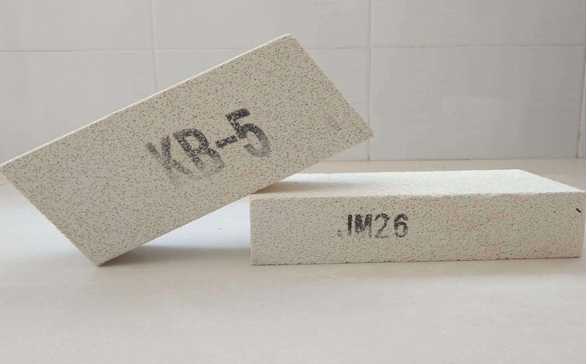

Brique isolante en mullite JM26

Brique isolante en mullite JM26

The refractoriness of JM26 mullite brick can reach above 1790℃. The load softening start temperature is 1400. Compressive strength at room temperature is 3-8MPa. Good thermal shock resistance. There are two types of sintered mullite bricks and fused mullite bricks. Sintered mullite bricks are made of high-alumina bauxite clinker as the main raw material, adding a small amount of clay or raw bauxite as a binder, and forming and firing. Fused mullite bricks are made of high alumina, industrial alumina and refractory clay as raw materials, and charcoal or coke fine particles are added as reducing agents. After molding, they are manufactured by reducing electric melting. The crystallization of fused mullite is larger than that of sintered mullite, and its thermal shock resistance is better than that of sintered products. Their high temperature performance mainly depends on the content of alumina and the uniformity of mullite phase and glass distribution. To

JM26 mullite insulation brick is made of high-bauxite clinker as the main material, plus a small amount of clay. It protects clay resources well, so when mullite insulation bricks appeared, they were products of modern technology. In the past, aluminum was something that nobles could use. However, modern technology allows aluminum as a resource to be used to produce various products.

The use temperature of different materials of JM series mullite bricks can be from 1300 degrees to 1600 degrees, and the body density can be 0.6, according to user requirements.

Between 0.8, 1.0 and 1.2, it acts on the high-temperature furnace to directly contact the flame, and has the characteristics of good insulation effect, high compressive strength, and low thermal conductivity. It is suitable for the insulation of electric kilns, various high-temperature rotary kilns, tunnel kilns, nitrogen gas kilns, etc. The crystallization of fused mullite is larger than that of sintered mullite, and its thermal shock resistance is better than that of sintered products. Their high temperature performance mainly depends on the content of alumina and the uniformity of mullite phase and glass distribution. Mullite bricks are mainly used for hot blast stove top, blast furnace body and bottom, regenerator of glass melting furnace, ceramic sintering kiln, dead corner lining of petroleum cracking system, etc.

The physical and chemical indexes of mullite poly light insulation brick:

| projet | Type 1500 | Type 1550 | Type 1600 |

| Maximum use temperature ℃ | 1500 | 1550 | 1600 |

| Al2O3% | ≥ 70 | ≥ 80 | ≥ 85 |

| SiO2% | ≤ 28 | ≤ 15 | ≤ 13 |

| Fe2O3% | ≤ 0.5 | ≤ 0.5 | ≤ 0.3 |

| Masse volumique en vrac g / cm3 | 1.3-1.5 | 1.4-1.7 | 1.6-1.8 |

| Résistance à la compression à température ambiante MPa | ≥ 8 | ≥ 8 | ≥ 10 |

| Température de démarrage de l’adoucissement de la charge ℃ (0.1 MPa, 0.6 %) | ≥ 1500 | ≥ 1550 | ≥ 1600 |

| Change rate of reburning line% | ± 0.5 | ± 0.5 | ± 0.3 |

| (1600℃×3h) | ≤ 0.6 | ≤ 0.7 | ≤ 0.8 |