- 15

- Nov

Use occasions of breathable bricks—refractory lining for ladle

Use occasions of briques respirantes—refractory lining for ladle

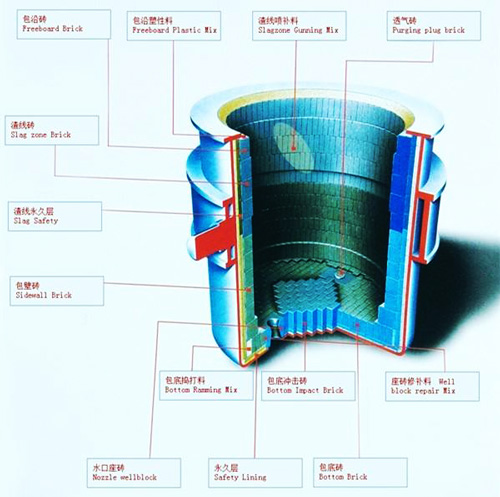

Permeable bricks are used in the ladle steelmaking process and have a certain life span, and the ladle itself also has a life limit. Ladle, also known as ladle, ladle, and large ladle, is an important thermal equipment for steelmaking manufacturers, mainly composed of a shell, a refractory lining, and a sliding nozzle mechanism. The ladle performs process operations such as refining treatment of molten steel. The use of ladle lining directly affects the output of steelmaking. Therefore, in pursuit of continuous improvement of the life of the ladle under the premise of ensuring safe use, it is necessary to reduce the consumption and cost of refractory material per ton of steel and increase the heat turnover rate.

(Picture) Ladle lining with refractory material

Ladle lining can be divided into working layer, permanent layer, slag line layer, heat insulation layer and so on. For the material of the permanent layer, considering the two factors of heat preservation and molten steel penetration, high-aluminum castables are selected. In order to enhance its thermal insulation performance, a layer of mullite lightweight brick is built between the high-alumina castable and the steel shell.

The working layer of the bottom of the ladle bears the impact of molten steel and relatively large static pressure, so corundum castable is selected. The magnesia-carbon bricks are built around the ventilation bricks and the nozzle block bricks, which can facilitate disassembly and repair and prevent excessive expansion. The working layer of the clad wall is affected by the carbon absorption of molten steel, tumbling erosion and slag erosion during refining. This part should have good erosion resistance, erosion resistance, and oxidation resistance. Corundum castable is used. Masonry of magnesia-carbon bricks at the slag line requires strong anti-oxidation and anti-erosion capabilities.

(Picture) Magnesia carbon brick