- 17

- Apr

What is the difference between fiberglass products for induction heating furnaces and fiberglass rods for induction heating furnaces?

What is the difference between fiberglass products for induction heating furnaces and fiberglass rods for fours à induction?

Tiges en fibre de verre pour fours à induction

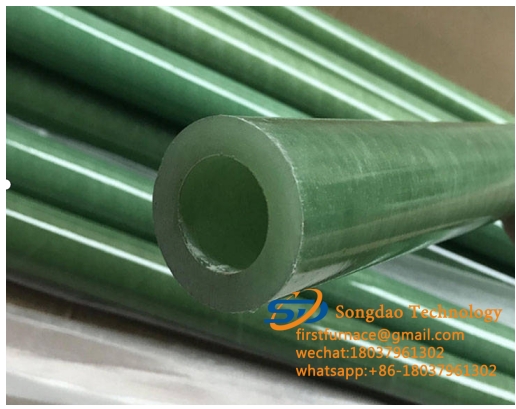

The glass fiber rod for induction heating furnace is a kind of pultruded glass fiber reinforced plastic composite material, which is a thermosetting plastic ductile material formed by continuous glass fiber roving and epoxy resin under the traction belt of the hot extrusion forming machine.

The resin-rich layer on the surface gives it excellent corrosion resistance, light weight, high compressive strength, good ductility, stable specifications and high precision. In addition, it has high-quality characteristics such as insulation, non-thermal conductivity, flame retardant, beautiful appearance and easy maintenance, so it is an excellent product to replace steel and other materials in engineering projects with corrosive natural environment.

Induction furnace fiberglass rod

Induction heating furnace glass fiber rod is a composite material that uses glass fiber and products (glass cloth, tape, felt, yarn, etc.) as the improvement material and resin material as the conventional material. The definition of composite material means that a material cannot be considered for application regulations, and must be composited by two or more materials to form another material that can be considered for everyone’s regulations, that is, composite materials.

Par exemple, un seul type de fibre de verre, malgré sa grande résistance à la compression, est lâche parmi les fibres chimiques. Il ne peut supporter que la force de traction, mais ne peut pas supporter les contraintes de flexion, de coupe et de compression, et il n’est pas facile de créer une forme géométrique fixe, c’est un corps mou.