- 17

- Sep

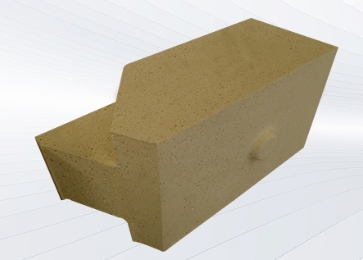

Shaped high alumina brick

Shaped high alumina brick

Product advantages: high refractoriness and load softening temperature, with the increase of Al2O3 content, the slag resistance performance is significantly improved.

Product application: Mainly used for lining of blast furnaces, hot blast furnaces, electric furnace tops, blast furnaces, reverberatory furnaces, and rotary kilns. In addition, high alumina bricks are also widely used as open hearth regenerative checker bricks, plugs for pouring systems, nozzle bricks, etc.

samfurin samfurin

The installation of high alumina bricks in the kiln is a very critical technology, especially in areas with complex structures, large changes in curvature and arched parts of the furnace roof. Poor installation of high alumina bricks may lead to high temperature blow-by or fire running. Standard refractory bricks will bring great difficulty to construction. Therefore, it is necessary to customize special-shaped high-alumina bricks, which can reduce the difficulty of construction and eliminate the gaps that may occur due to construction difficulties when using standard high-alumina bricks. The life of the kiln.

The shape quality of special-shaped high alumina bricks should meet the following requirements:

(1) Dimensional tolerance: height tolerance ± 2%; wedge-shaped surface large and small head width tolerance ± 2mm; size difference tolerance ± 1mm; length tolerance ± 1%. Custom-made high alumina bricks, the difference is 2mm.

(2) Edge loss. Allow the hot or cold side to have two sides damaged up to 40mm long and 5mm deep; but not allowed to exceed.

(3) Angular loss. There is only one corner damage custom-made high alumina bricks on the hot and cold surfaces, and the total length of the three edges of the corner damage should not exceed 50mm. Angle loss not exceeding 20mm is not considered.

(4) Cracks. The brick surface is allowed to have hair-like micro cracks; no cracks parallel to the worn surface are allowed; other cracks not longer than 40mm and not wider than 0.2mm are allowed.

(5) Pits, melting marks and bulges. Allowable pits and melting marks are 10mm in diameter and 10mm in depth; bulge is 0.5mm. High alumina bricks with various rough edges in a batch of bricks shall not exceed 70% of the total.

Alamar jiki da sinadarai

| Matsayi/Index | Babban tubalin alumina | Babban tubalin alumina na sakandare | Babban tubalin alumina mai hawa uku | Babban tubalin alumina babba |

| LZ-75 | LZ-65 | LZ-55 | LZ-80 | |

| AL203 ≧ | 75 | 65 | 55 | 80 |

| Fe203% | 2.5 | 2.5 | 2.6 | 2.0 |

| Ensarancin yawa g / cm2 | 2.5 | 2.4 | 2.2 | 2.7 |

| Ƙarfin matsawa a ɗaki mai dumama MPa> | 70 | 60 | 50 | 80 |

| Load softening zazzabi ° C | 1520 | 1480 | 1420 | 1530 |

| Refractoriness ° C> | 1790 | 1770 | 1770 | 1790 |

| Porosity na bayyane% | 24 | 24 | 26 | 22 |

| Canjin canjin layin dindindin% | -0.3 | -0.4 | -0.4 | -0.2 |