- 16

- Nov

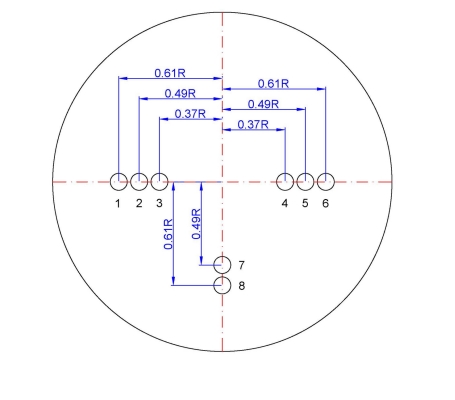

Arrangement of breathable bricks at the bottom of the ladle

Arrangement of सांस लेने वाली ईंटें at the bottom of the ladle

(चित्र) डीडब्ल्यू श्रृंखला भट्ठा प्रकार सांस ईंट

With the development of the steelmaking industry, there are many types and sizes of ladle in the domestic steelmaking industry. At present, the common layout of ventilating bricks at the bottom of the ladle includes single venting brick single blowing, radial symmetric double blowing, radial asymmetric double blowing, vertical double blowing, etc.

1 Single breathable brick blowing

Ladles of more than 100 tons are mostly sprayed with single or double breathable bricks. The effect of eccentric spraying is better than that of central spraying. The position of the blowing holes is best at 1/3 to 2/3. As shown in the figure, the air-permeable bricks (hole 1, hole 2, hole 3) are sprayed with argon gas. To

2 Radial symmetrical double blowing

Two air-permeable bricks (hole 1 and hole 6, hole 2 and hole 5, hole 3 and hole 4) which are distributed on the same diameter of the ladle bottom and are symmetrical about the center of the ladle bottom surface are sprayed at the same time.

3 Radial asymmetric double blow

Two air-permeable bricks (hole 1 and hole 4, hole 1 and hole 6, hole 2 and hole 6) distributed on the same diameter but asymmetrically on the bottom of the bag. To

4 Vertical double blow

The two air-permeable bricks are in double blows with the diameters perpendicular to each other (hole 6 is blown with holes 1, 2, 3; hole 8 is blown with holes 1, 2, 3 respectively).

समापन टिप्पणी

Regardless of the arrangement method, it needs to be comprehensively considered in accordance with the actual situation, mainly by changing the size of the air supply, measuring the mixing time, and selecting the best ventilating brick layout plan.