- 12

- Oct

What do you need to know when buying refractory bricks?

What do you need to know when buying refractory bricks?

What do you need to know when buying refractory bricks? What kind of furnace lining is used for refractory bricks? Can refractory bricks achieve practical application effects? How to purchase refractory bricks to achieve good results? Combining the actual situation, expounds the refractory brick procurement Issues that should be paid attention to.

1. Kiln location using refractory bricks

According to the structure of the furnace, the working characteristics and operating conditions of each part of the furnace, refractory bricks are selected to achieve targeted selection. For example, the lining and bottom of various smelting furnaces below the slag line (such as furnaces and reverberatory furnaces) are mainly chemically attacked by slag and metal melt, followed by thermal stress caused by sudden temperature changes. The masonry generally chooses magnesia and magnesia-chrome refractory bricks with good slag resistance. The above slag line can choose magnesia alumina brick, magnesia chrome brick or high alumina refractory brick.

2. Ensure the normal operation and overall life of the furnace

As the lining of the kiln, the normal operation and overall service life of the kiln must be guaranteed. Reasonably configure various refractory bricks used in various parts of the furnace. When determining the various parts of the furnace and the materials of each layer of the same part, avoid chemical reactions and melting damage between different refractory bricks, and ensure that the loss of each part is balanced, or take reasonable process measures to balance the loss and ensure the overall life of the furnace.

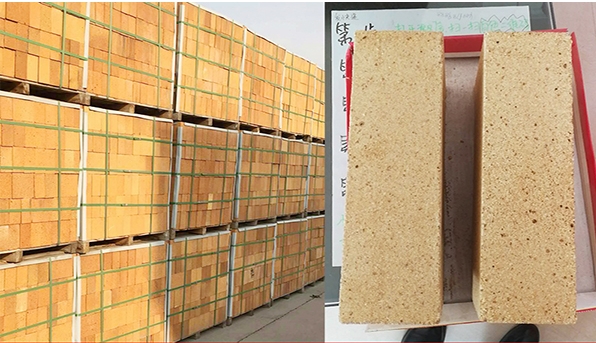

3. The characteristics of refractory bricks

When purchasing refractory bricks, you should master the basic knowledge of refractory bricks, such as the composition of refractory bricks, the physical properties and working performance of refractory bricks, and whether it can achieve the expected effect as a furnace lining, so as to better exert the excellent characteristics of refractory bricks. For example, silica bricks for coke ovens have a high softening temperature under load and can resist acid slag erosion, but their thermal shock resistance is poor and can only be used for coke oven partition walls. Their soft load characteristics can be used in long-term high temperature environments.

2. Refractory brick manufacturers

As a purchaser of refractory bricks, to purchase commonly used refractory bricks, you only need to determine the index, size, performance and other information of the refractory bricks, and consult the refractory brick manufacturer whether it can be produced, whether it can meet the specified requirements, and whether the processed refractory bricks can meet the requirements Characteristics and other information, this is the most basic integrity of refractory brick manufacturers.