- 10

- Dec

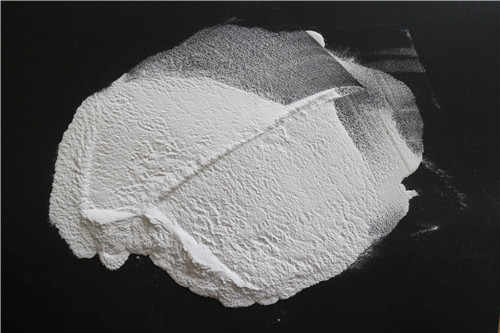

Qhov sib txawv ntawm cov hmoov dawb corundum thiab alumina hmoov

Qhov txawv ntawm dawb corundum hmoov thiab alumina hmoov

Dawb corundum hmoov thiab alumina hmoov muaj tib lub ntsej muag thiab cov npe zoo sib xws. Ntau tus neeg xav qhia qhov txawv ntawm lawv. Cov nram qab no Qianjiaxin Refractories yuav paub qhov txawv ntawm nws tus kheej muaj pes tsawg leeg.

1. Dawb corundum hmoov

(1) Crystal daim ntawv: trigonal crystal system;

(2) Qhov ceev: 3.90 g / cm3;

(3) Hardness: Knoop hardness 2000-2200Kg/mm2, Mohs hardness 9.0;

(4) Melting point: 2250C;

(5) Ua haujlwm kub siab tshaj plaws: 1900C;

(6) Cov cua kub tshwj xeeb (Cal / gC): 0.26 (20-90C);

(7) Thermal conductivity: 900C ntawm chav tsev kub (Cal/cm3.sec.C);

(8) Refractive index: e=1.760 w=1.768 (Na kab);

(9) Coefficient ntawm linear expansion: (7-9) * 10^-6 / K (0-1600C).

2. Alumina hmoov

(1) Cov tsos: dawb hmoov, crystalline theem γ theem;

(2) Qhov nruab nrab particle loj (nm): 20 ± 5;

(3) Cov ntsiab lus %: ntau dua 99.9%;

(4) Melting point: 2010 ℃ -2050 ℃;

(5) Kub taw tes: 2980 ℃;

(6) Cov txheeb ze ntom ntom (dej = 1): 3.97-4.0;

(7) Xim: dawb, xiav tsaus tom qab calcination.

Dawb corundum hmoov yuav siv tau raws li kev sib cuag xov xwm, insulators thiab precision casting xuab zeb, thiab lwm yam Alumina hmoov ze yuav siv tau nyob rau hauv tshav kub conduction, polishing, electroplating, catalyst, thiab lwm yam.