- 27

- Dec

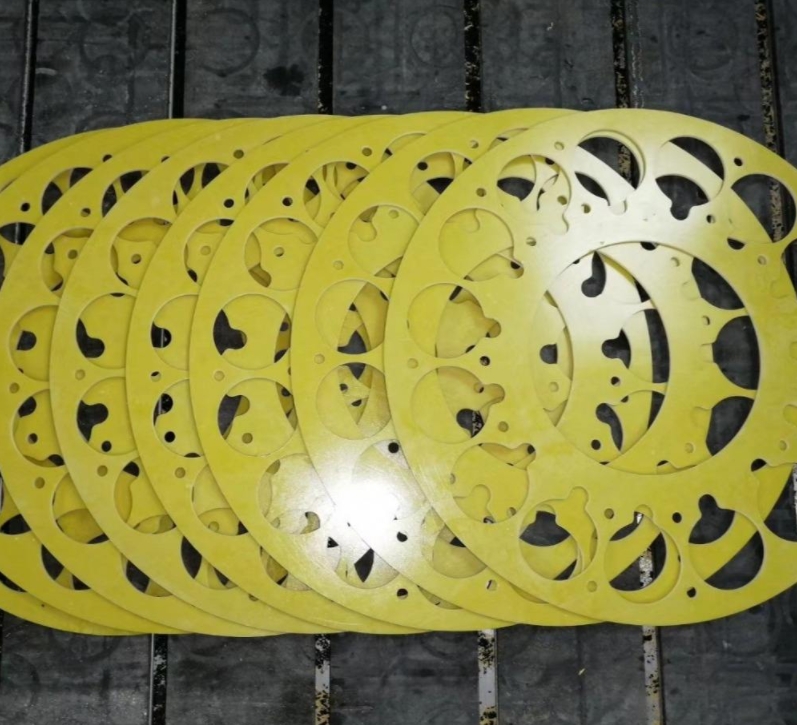

Epoxy pad khoom ua haujlwm

Epoxy ncoo khoom kev ua tau zoo

1. Nws muaj cov khoom siv hluav taws xob siab thiab dielectric, zoo thaum tshav kub kub thiab noo noo tsis kam, thiab muaj kev ua haujlwm zoo, thiab qib cua sov yog qib B.

2. Nws yog qhov tsim nyog rau kev siv cov khoom siv hluav taws xob hauv cov khoom siv hluav taws xob thiab cov khoom siv hluav taws xob, thiab tuaj yeem siv rau hauv qhov chaw ntub dej thiab cov roj hloov pauv.

3. Nrog cov khoom siv hluav taws xob siab thiab hluav taws xob, cov khoom siv no tau siv dav hauv cov khoom siv insulating thiab cov khoom siv hauv cov tshuab hluav taws xob, lub cev muaj zog, thiab cov khoom siv hluav taws xob. Nws kuj yog heev haum rau transformer roj siab ib puag ncig thiab humidity ib puag ncig.

4. The reaction between the epoxy resin and the curing agent used is carried out by direct addition reaction or the ring-opening polymerization reaction of epoxy groups in the resin molecule, and no water or other volatile by-products are released. Compared with unsaturated polyester resins and phenolic resins, they show very low shrinkage (less than 2%) during curing.