- 31

- May

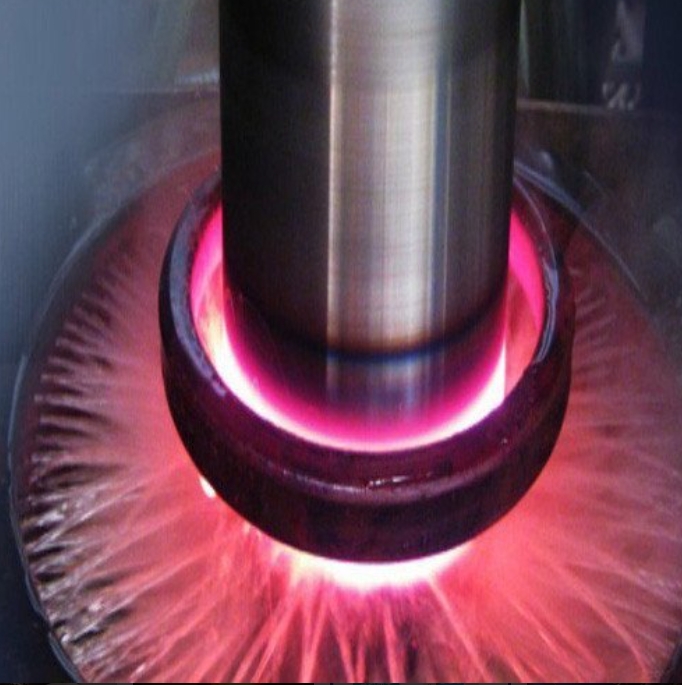

The advantages of high frequency induction heating machine in the surface quenching of metal workpieces

Qhov zoo ntawm cov siab zaus induction cua sov tshuab in the surface quenching of metal workpieces

The surface quenching of metal workpieces by high-frequency induction heating machine is compared with ordinary and traditional heating and quenching methods: flame heating surface quenching, electrical contact heating surface quenching, electrolyte heating surface quenching, laser heating surface quenching, electron beam heating surface quenching, etc. Below, the summary has the following advantages:

1. The heating speed is extremely fast, which can expand the transformation temperature range of the workpiece A and shorten the transformation time.

2. After quenching, the surface layer of the workpiece can get extremely fine cryptocrystalline martensite, and the hardness is slightly higher (2-3HRC). Professional high frequency heating machine with low brittleness and high fatigue strength.

3. Cov workpieces kho los ntawm cov txheej txheem no tsis yooj yim rau oxidized thiab decarburized, thiab txawm tias qee qhov workpieces tuaj yeem ncaj qha sib dhos thiab siv tom qab kho.

- The hardened layer is deep, easy to control and operate, easy to realize mechanization and automation.