- 31

- May

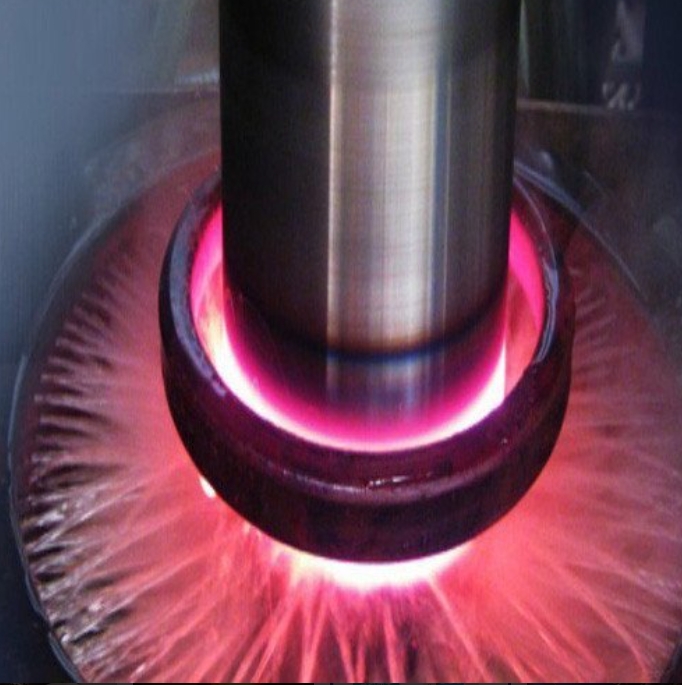

The advantages of high frequency induction heating machine in the surface quenching of metal workpieces

A Nagyfrekvenciás indukciós fűtőgép in the surface quenching of metal workpieces

The surface quenching of metal workpieces by high-frequency induction heating machine is compared with ordinary and traditional heating and quenching methods: flame heating surface quenching, electrical contact heating surface quenching, electrolyte heating surface quenching, laser heating surface quenching, electron beam heating surface quenching, etc. Below, the summary has the following advantages:

1. The heating speed is extremely fast, which can expand the transformation temperature range of the workpiece A and shorten the transformation time.

2. After quenching, the surface layer of the workpiece can get extremely fine cryptocrystalline martensite, and the hardness is slightly higher (2-3HRC). Professional high frequency heating machine with low brittleness and high fatigue strength.

3. Az ezzel az eljárással kezelt munkadarabok nem könnyen oxidálhatók és szénmentesíthetők, sőt egyes munkadarabok közvetlenül összeszerelhetők és a kezelés után felhasználhatók.

- The hardened layer is deep, easy to control and operate, easy to realize mechanization and automation.