- 28

- Dec

Basic introduction of fused mullite

Basic introduction of fused mullite

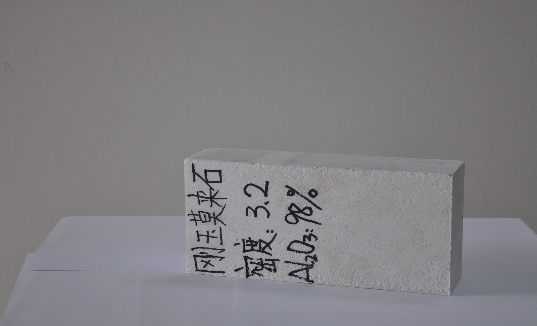

Fused mullite bricks are commonly known as iron bricks, which are weakly acidic refractory materials. The manufacturing method is the same as the production process of fused zirconia corundum bricks, that is, the carefully selected and pretreated raw materials are put into an electric furnace to melt, and after a period of time, they are injected into the model to form. The main component is Al2O3, the content of which can reach more than 75%, and the content of SiO2 is about 15%. In addition to the corundum crystals, it is mainly mullite crystals. The glass phase is filled between the crystal phases. The density of fused mullite bricks is not as high as that of fused zirconia corundum bricks, but the density also reaches 2.7~3.2g/cm3. The refractoriness is 1730~1800°C. The load softening temperature is 1700°C or higher.