- 08

- Sep

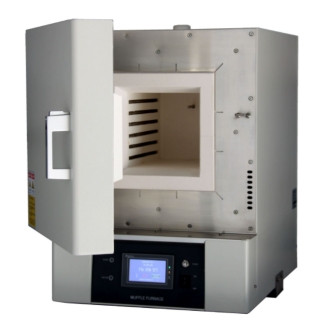

Correct operation method of box type resistance furnace

Correct operation method of box type resistance furnace

Correctly use the box-type resistance furnace maintenance standard operation, the maximum temperature of 1200 ℃ can not be used for a long time, to avoid overheating, overload operation, it is strictly forbidden to prevent the sudden increase in high temperature and power-off quenching, so as not to damage the furnace and heating wire. For indoor use, the ambient temperature is -10~40°C, the surrounding environment does not contain conductive dust, flammable and explosive materials and gases, and corrosive gases that seriously damage metals. The relative humidity of the environment does not exceed 85%RH, and there is no vibration and Bumps regularly check whether the contact of the circuit system connection is good. ,

1. The theoretical calculation method of box-type resistance furnace. The main parameters are production, temperature and heating time. There are three empirical calculation methods: calculate power according to furnace volume and working temperature or calculate power according to furnace surface area and working temperature, or according to the same type of furnace The output is calculated by analogy.

2. The general calculation ability is mainly based on one method, and is checked and corrected by another method or two methods. After the power is determined, the power is distributed according to the partition conditions of the box-type resistance furnace, the form of the heating element is selected, and the material is selected , Calculate the parameters, including cold resistance, power supply voltage, wire diameter and length.

3. The material selection of box-type resistance furnace should consider the material’s oxidation resistance, high temperature resistance, carburization resistance, processability and surface load. The strip heating element bears a slightly larger surface load than the filament heating element and can be increased. 50℃