- 04

- Nov

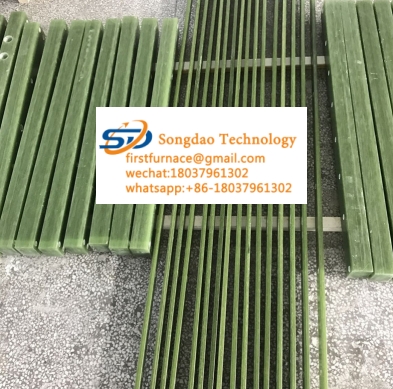

Kọlụm mkpuchi maka ọkụ induction

Kọlụm mkpuchi maka ọkụ induction

A na-eme ya nke eriri aramid dị elu na eriri iko etinyere na matrix epoxy resin matrix mgbe oke okpomọkụ pultrusion gasịrị. Ọ nwere njirimara nke ike dị elu nke ukwuu, nkwụsi ike dị mma, acid na alkali eguzogide, corrosion eguzogide na ndị ọzọ magburu onwe elu okpomọkụ na-eguzogide. Ngwaahịa ndị dị mma maka ngwa eletriki eletrik dị elu dị ka osisi aluminom electrolytic, osisi nchara, akụrụngwa igwe ọkụ ọkụ ọkụ, ngwa eletrik UHV, ubi ikuku, ndị na-agbanwe agbanwe, capacitors, reactors, nnukwu ọkụ ọkụ ọkụ, wdg.

A na-eme kọlụm mkpuchi nke ọkụ induction nke eriri aramid dị elu yana eriri iko etinyere na matrix epoxy resin matrix mgbe oke okpomọkụ pultrusion gasịrị. Ọ nwere njirimara nke ike dị elu nke ukwuu, nkwụsi ike dị mma, acid na alkali eguzogide, corrosion eguzogide na ndị ọzọ magburu onwe elu okpomọkụ na-eguzogide. Ngwaahịa dabara adaba maka osisi aluminom electrolytic, osisi nchara, akụrụngwa igwe igwe na-ekpo ọkụ, ngwa eletriki eletrik dị elu, ogige ikuku, ndị na-agbanwe agbanwe, ndị na-eme ihe, ndị na-ebugharị, mgba ọkụ voltaji na ngwa eletriki ndị ọzọ dị elu.

1. N’ihi na-aga n’ihu pultrusion nke aramid eriri na iko eriri, ngwaahịa nwere magburu onwe iguzogide n’ibu nrụgide na n’ibu esemokwu. Ike ike ya ruru 1500MPa, bụ nke karịrị ike mgbanye nke No. 45 nkenke nkedo nkedo, nke bụ 570Mpa. Ọmarịcha arụmọrụ eletriki, na-anagide ọkwa voltaji nke oke voltaji 10kV-1000kV. Nguzogide corrosion siri ike, ike na-ehulata dị elu, ọ dịghị mfe ịgbagọ, dị mfe iji na ihe ndị ọzọ.

2. Ọnọdụ okpomọkụ na-arụ ọrụ ogologo oge nke ngwaahịa a bụ 170-210 ℃; Oke kacha arụ ọrụ dị mkpụmkpụ mkpụmkpụ ngwaahịa bụ 260 ℃ (erughị 5 sekọnd).

3. N’ihi iji onye nnọchi anya ntọhapụ dị elu, a na-ekwe nkwa elu ngwaahịa ahụ ka ọ dị ezigbo mma, na-enweghị ọdịiche agba, na-enweghị burrs, na enweghị ọkọ.

4. Klas na -eguzogide ọkwa na mkpuchi ihe ngwaahịa ruru H ọkwa.