- 12

- Dec

Clay refractory brick Lightweight refractory brick Refractory brick price

Clay refractory brick Lightweight refractory brick Refractory brick price

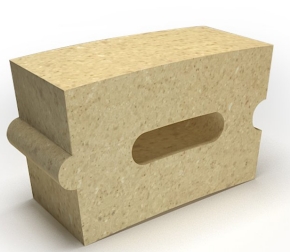

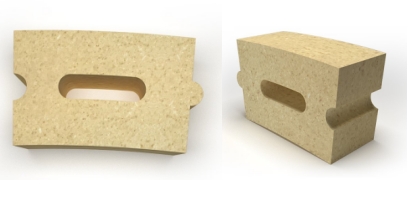

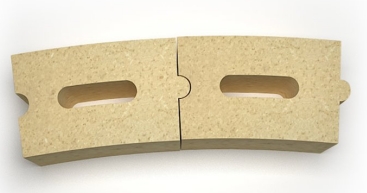

A compact super high-alumina brick with high compressive strength and high density. The firing temperature of this high-alumina brick is similar to that of ordinary high-alumina bricks, with low energy consumption and low cost. The service life on the kiln is twice that of ordinary high-alumina refractory bricks. It is based on the special grade bauxite clinker calcined in the rotary kiln as the aggregate (grain size 1smm-3smm), weight ratio: 40%~45%, plus bauxite clinker powder and fine powder: 45% to 51%, soft Clay: 7% to 10%, a small amount of kyanite powder: 3 to 5%, and adhesive pulp waste liquid 4% to 5% and other components.

Ngwaahịa ezigbo gbaa

atụmatụ nke ngwaahịa

Product function: Super high-alumina bricks are mainly used for electric furnace cover (furnace top), blast furnace (furnace body), hot blast stove partition wall, ladle lining, ladle, iron wagon, cement kiln, glass kiln, etc. Furnace lining. It is widely used in ironmaking, steelmaking, chemical, cement and other industries.

Production process: Super high-alumina brick is a high-alumina refractory brick with an aluminum oxide content of more than 80%. Because the refractory temperature is greater than 1790 degrees Celsius, it is a refractory material. It is a common material for the lining of high-temperature kilns. It is made of special-grade high alumina bauxite clinker as the main raw material, soft clay and waste pulp and paper liquid as the binding agent to form a mud, which is formed by high-pressure forming, drying, and high-temperature firing. It is a sintered refractory brick.