- 18

- Jan

Advantages of plate heat exchangers for induction melting furnaces

Advantages of plate heat exchangers for induction melting furnaces

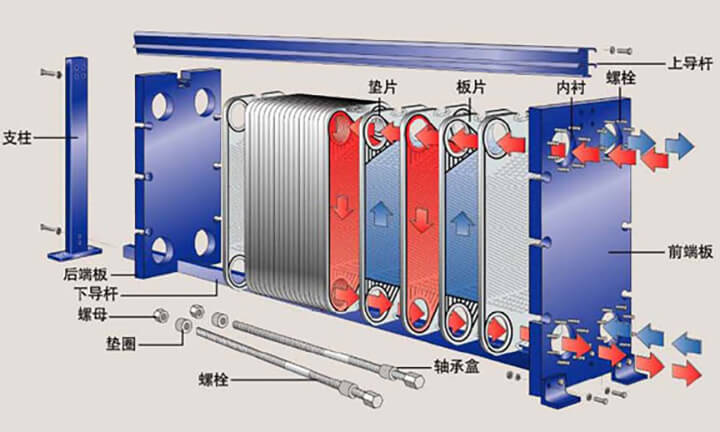

The plate heat exchanger for ọkụ na-agbaze ọkụ is a new type of high-efficiency heat exchanger composed of a series of metal sheets with a certain corrugated shape. Thin rectangular channels are formed between various plates, and heat exchange is carried out through the plates. Plate heat exchangers are ideal equipment for liquid-liquid and liquid-vapor heat exchange. It has the characteristics of high heat exchange efficiency, low heat loss, compact and lightweight structure, small footprint, convenient installation and cleaning, wide application, long service life and so on. Under the same pressure loss, its heat transfer coefficient is 3-5 times higher than that of the tubular heat exchanger, covering an area of one third of that of the tubular heat exchanger, and the heat recovery rate can be as high as 90% or more.

Plate heat exchangers are optimized for different processes

1 Efficient diversion area

The unique diversion area design is more in-depth application, which can help you save research and development costs and make your products well-known.

2Ingenious suspension positioning lock system

The unique suspension positioning lock system makes it easier for the plate to hang on the guide rod and lock it. It also allows you to easily add or replace plates at any time, improving productivity, saving space and saving costs. Let your development be full of imagination.

3Compact design

Reasonable selection design makes our heat exchanger smaller, which allows you to develop a more compact system, reduce transportation costs, make your products more price-competitive, and enhance your green brand.