- 14

- Apr

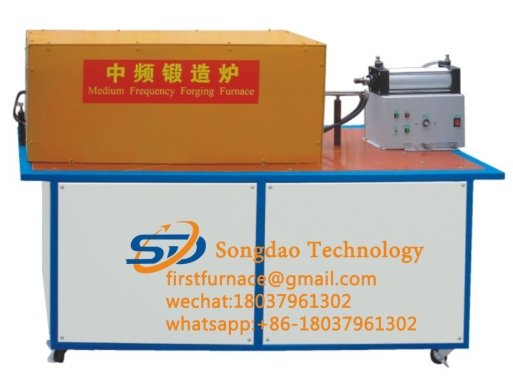

Mpaghara ngwa nke ụdị dị iche iche nke igwe kpo oku induction

Ngwa ubi nke dị iche iche ụdị nke igwe eji eme oku:

A, 50 ngwa igwe:

1. Diathermic forging nke gburugburu ígwè, Ogwe na ndị ọzọ workpieces na a dayameta nke na-erughị Φ25mm;

2. Ngwunye diski na dayameta nke Φ150mm na ogwe osisi nwere dayameta nke Φ50mm ma ọ bụ obere;

3. Ịkwụsị okporo ụzọ nduzi nke obere ngwá ọrụ igwe;

4. Welding nke geological drill ibe n’ibe.

B, 80 ngwa igwe dị nso:

1. Diathermic forging nke gburugburu ígwè, Ogwe na ndị ọzọ workpieces na a dayameta nke na-erughị Φ35mm;

2. Ịkwụsi ike nke diski na dayameta Φ260mm na ogwe ndị nwere dayameta n’okpuru Φ80mm;

3. Ngwunye ụgbọ okporo ígwè na-eduzi ngwá ọrụ igwe na akụkụ obe n’okpuru 200mm.

Ngwa igwe C. 120 oke:

1. Diathermic forging nke gburugburu ígwè, Ogwe na ndị ọzọ workpieces na a dayameta nke na-erughị Φ45mm;

2. Ịkwụsi ike nke diski na dayameta nke Φ350mm na ogwe osisi na dayameta nke Φ100mm ma ọ bụ obere;

3. Nkwụsị ụgbọ okporo ígwè igwe.

D. 160 igwe ngwa oke:

1. Diathermic forging nke gburugburu ígwè, Ogwe na ndị ọzọ workpieces na a dayameta nke na-erughị Φ50mm;

2. Ịkwụsi ike nke diski na dayameta nke Φ400mm, sprockets nke Φ500mm, ogwe n’okpuru Φ150mm;

3. Nkwụsị ụgbọ okporo ígwè igwe.

E, 200 nkeji ngwa ngwa igwe:

1. Diathermic forging nke gburugburu ígwè, square ígwè, mmanya na ndị ọzọ workpieces na a dayameta nke na-erughị Φ60mm;

2. Ngwunye gia na dayameta nke Φ500mm;

3. Φ800mm sprocket na-emenyụ, otu eze nwere ike imenyụ ya na modul nke ihe dị ka 50mm, na Φ250mm bụ ihe na-eme ka ogwe osisi quenching, nkwụsị ahụ bụ otu, na mmetụta dị mma.

F, 300 nkeji ngwa ngwa igwe:

Diathermic forging nke gburugburu ígwè, Ogwe na ndị ọzọ workpieces na a dayameta nke na-erughị Φ70mm.

Ngwa nso nke G, igwe oge etiti 500:

Integral diathermy forging nke gburugburu ígwè, Ogwe na ndị ọzọ workpieces na a dayameta nke na-erughị Φ120mm.