- 12

- Feb

What are the main components of glass fiber rods and glass fiber rods for induction heating furnaces?

What are the main components of glass fiber rods and glass fiber rods for induction heating furnaces?

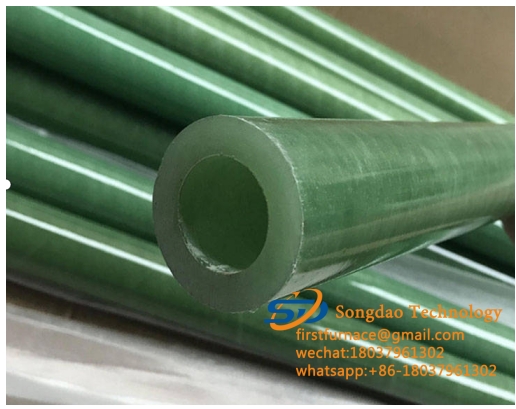

Glass fiber rod and ដំបងសរសៃកញ្ចក់ (formerly called glass fiber) for induction heating furnace are inorganic non-metallic materials with excellent performance. It has many kinds. Its advantages are good insulation, heat resistance, corrosion resistance and high mechanical strength. However, its disadvantage is brittleness and poor wear resistance. It is made of pyrophyllite, quartz sand, limestone, dolomite, boron calcite and brucite as raw materials, which are melted, drawn, wound and weaved at high temperature. Its monofilament diameter is several microns to twenty microns, which is equivalent to 1/20-1/5 of a hair. Each bundle of fiber precursors consists of hundreds or even hundreds. Thousands of monofilaments. Fiberglass rods and fiberglass rods for induction heating furnaces are often used as reinforcing materials in economic fields such as composite materials, electrical insulating materials and insulating materials, and circuit substrates.

The main components of glass fiber rods and glass fiber rods for induction heating furnaces are silica, alumina, calcium oxide, boron oxide, magnesium oxide and sodium oxide. According to the alkali content of glass, it can be divided into alkali-free glass fiber (0%-2% sodium oxide, belonging to aluminoborosilicate glass), medium alkali glass fiber (8%-12% sodium oxide, belonging to boron-containing or borosilicate-free glass) sodium glass) and high alkali glass. Glass fiber (sodium oxide, more than 13%, sodium silicate glass).