- 28

- Jan

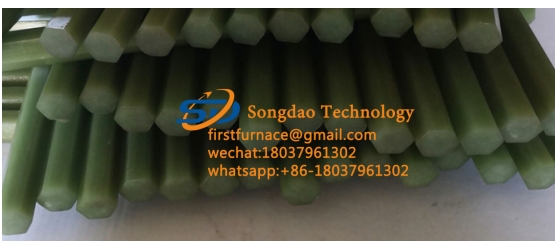

Fiberglass Rods for Induction Furnaces

Fiberglass Rods for Induction Furnaces

There are many ways to classify glass fibers. It can usually be classified in terms of glass material composition, monofilament diameter, fiber appearance, production method and fiber characteristics. 1. Classification by glass material composition This classification method is mainly used for the classification of continuous glass fibers. Usually, the difference is based on the content of different alkali metal oxides, and alkali metal oxides usually refer to sodium oxide and potassium oxide. In the vitreous guess, it is introduced by soda ash, Glauber’s salt, feldspar and other substances. Alkali metal oxide is one of the primary components of general glass, and the primary function of glass fiber mat is to lower the melting point of glass. However, the higher the content of alkali metal oxides in glass, the corresponding decrease in its chemical stability, electrical insulating function and strength. Therefore, for glass fibers with different uses, glass components with different alkali contents should be selected. Then the alkali content of glass fiber components is often selected as a symbol of continuous glass fibers with different uses.

Is the glass fiber rod used in the induction heating furnace a glass rod? No, the glass fiber rod for induction heating furnace is a kind of glass fiber reinforced plastic product, to be precise, it is a kind of product of glass fiber reinforced plastic pultrusion technology. It is made of glass fiber roving and thermosetting resin, which is related to glass. It is only glass fiber, in fact, it is a kind of plastic, the full name is glass fiber reinforced plastic rod.