- 10

- Aug

Structure of induction heating pit annealing furnace

Structure of induction heating pit annealing furnace

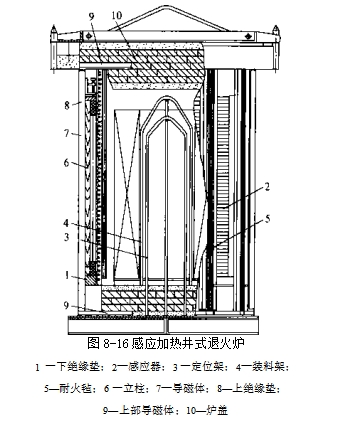

The figure shows the structure of the induction heating pit annealing furnace.

Induction heating pit furnaces can be used to replace traditional annealing furnaces with long production cycles, high energy consumption, large oxidation losses and environmental pollution, such as pit resistance furnaces, electric hood furnaces, and fuel-heated continuous annealing furnaces.

The induction heating pit annealing furnace is mainly used for the annealing treatment of coiled wire rod, non-hot-rolled controlled cold coil, and cold drawn semi-finished steel. This annealing heating method can achieve rapid temperature rise, uniform temperature, small oxidation loss, energy saving and no pollution to the environment.

The structure of the induction heating pit annealing furnace is as follows.

(1) Electrical system The electrical system of the furnace includes power frequency heating power supply, induction coil, electrical control and other parts. The start and stop of the furnace are operated manually, and the furnace temperature can be automatically

Dynamic temperature control. The total heating power of the furnace is 270kW, and the upper, middle and lower furnaces are composed of 3 groups of induction coils. In order to maintain the uniformity of the upper and lower temperatures in the furnace and prevent the temperature of the furnace bottom and furnace mouth from being low, corresponding measures have been taken in the design of the inductor. In addition, the overall height of the induction coil is greater than the height of the material column to ensure that the upper and lower temperatures of the material column are consistent.

Dynamic temperature control. The total heating power of the furnace is 270kW, and the upper, middle and lower furnaces are composed of 3 groups of induction coils. In order to maintain the uniformity of the upper and lower temperatures in the furnace and prevent the temperature of the furnace bottom and furnace mouth from being low, corresponding measures have been taken in the design of the inductor. In addition, the overall height of the induction coil is greater than the height of the material column to ensure that the upper and lower temperatures of the material column are consistent.

(2) The structure of the furnace body In addition to the induction coil and its accessory parts, the furnace body also has a furnace cover and lifting parts, a heat-insulating refractory lining, a furnace base and upper and lower insulating backing plates, a furnace frame, upper and side magnetizers, etc. Its overall structure is similar to pit electric furnace and induction furnace for smelting. The diameter of the furnace is 1.8m, the height is 2.5m, and the charging amount is 1-3T. When the loading volume is 1T, 10 disks with a diameter of 5-10mm can be loaded, the mass is about 1T, the outer diameter of the loaded coil is 1.2m, and the inner diameter is about 0.8m; when the loading volume is 3t, it is equivalent Load 7 discs of steel material with a diameter of 18mm, a coil outer diameter of 1.4m, and an inner diameter of 0.95m.