- 25

- Nov

The pros and cons of induction melting furnace

The pros and cons of induction melting furnace

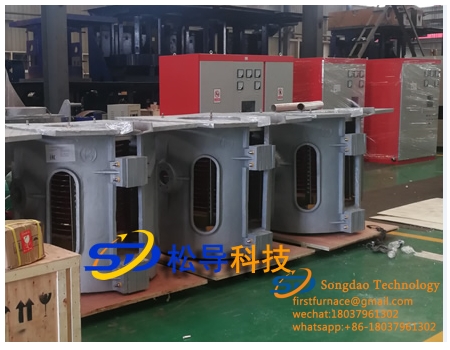

The charge in the induction melting furnace generates heat by itself, so it has higher efficiency than other indirect heating, low power consumption, low metal burnout, low pollution to the power grid and air, so it is still the most effective way to melt all kinds of metals so far. Effective and most environmentally friendly equipment. In order to further save energy and protect the environment, domestic manufacturers of induction melting furnaces have developed the most advanced solid-state induction melting furnace (series inverter circuit, frequency modulation power adjustment), which saves 10% of electricity and reduces the interference to the power grid by half.

Things always have their advantages and disadvantages.

Since the induction melting furnace is induction heating, induction electricity exists in the charge and the furnace shell. In particular, large-tonnage furnaces and energy-saving, environmentally-friendly solid-state induction melting furnaces have higher induction power. In addition, the thickness of the lining of the induction melting furnace is relatively thin. Therefore, pay special attention to safety during use.

Induction melting furnaces and gas burning furnaces are widely used and widely used in our Xinghua area, which has provided a lot of help for the development of the local economy. But we must pay special attention to the safe use of induction melting furnaces and gas burning furnaces.