- 10

- May

Basic precautions for safe operation of high frequency induction hardening equipment

Basic precautions for safe operation of high frequency induction hardening equipment

1. Please wear work clothes, work cap and protective glasses when working.

2. Be careful not to move or damage the warning signs installed on the machine tool;

3. Be careful not to place obstacles around the machine tool, and the working space should be large enough;

4. Clean up the burrs, iron filings and sundries on the processed parts. To prevent short circuit during induction heating and burn the workpiece;

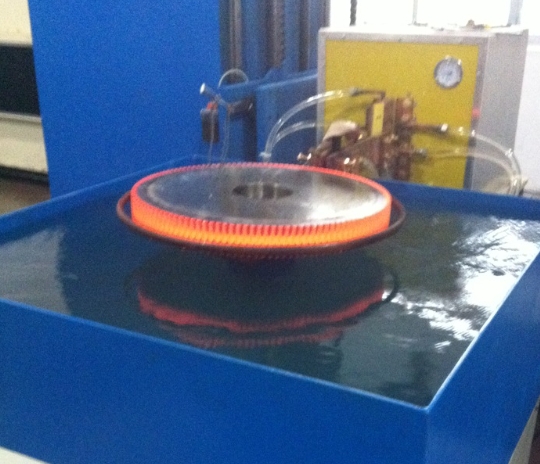

5. Select the sensor that matches the workpiece according to the size of the workpiece. The gap between the workpiece and the sensor is 3~5mm. (refers to shafts and gears, except for special parts)

6. It is not allowed to use compressed air to clean machine tools, electrical cabinets and NC units.

7. Equipment operators are not allowed to modify or delete the machine program at will, and the connection line of the NC unit of the electrical cabinet is strictly prohibited to be changed.