- 06

- Oct

Maintenance of the air-permeable bricks for the air supply element at the bottom of the ladle

Maintenance of the വായു-പ്രവേശന ഇഷ്ടികകൾ for the air supply element at the bottom of the ladle

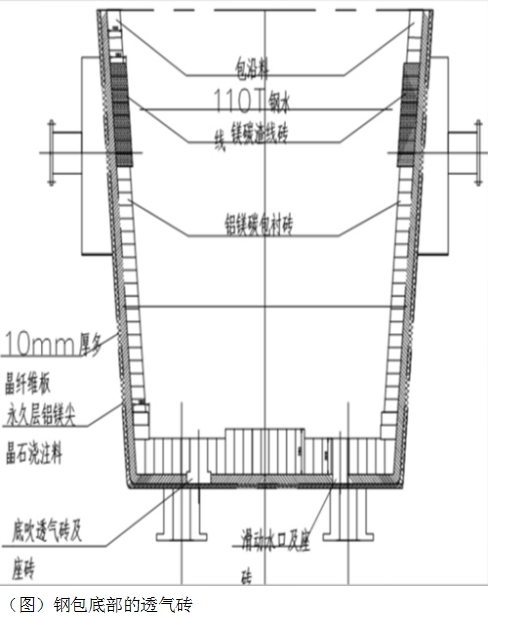

The air-supply element venting brick is the key equipment for ladle refining manufacturers. From the perspective of its use and development, in order to protect the air-supply element, it is generally equipped with a protective cover brick. brick. The air-supply element ventilated bricks are combined with protective seat bricks and are jointly laid on the bottom of the ladle. The life of the bottom air-supply element ventilating brick is not only related to its own structure, air source, material, operating technology and the material of the protective seat brick, but also to the quality of the ladle masonry; the quality of the ladle is not good. The impact is very large.

(Picture) Breathable brick for air supply element

Due to the use of air-permeable bricks for the air supply element at the bottom of the bag, the temperature of the refractory materials around the air-permeable bricks will change drastically, and the stirring power of the molten pool will also be strengthened. In addition, the method and quality of ladle masonry are also very important to the life of the ladle and gas supply components. With the increase of the cross-sectional shape of the brick, the thermal stress also increases, which is prone to spalling loss. The air-permeable brick of the air supply element should be vertical to the bottom of the ladle. After the air-permeable brick is built, it should be higher than or level with the bottom surface of the ladle, and the unevenness should not exceed the standard requirements. The takeover of the brick tail pipe was crushed.

(Picture) Breathable bricks at the bottom of the ladle