- 07

- Jan

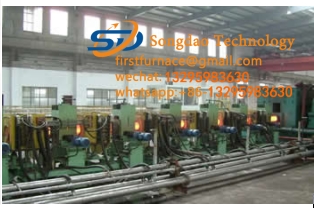

Thick-walled steel pipe annealing equipment

Thick-walled steel pipe annealing equipment

The thick-wall steel pipe intermediate frequency annealing equipment is composed of PLC and human-machine interface. It has a convenient management system, all-digital, high-depth adjustable parameters, strict management system, and perfect one-key restoration system. It can be used according to different countries and regions. Provide corresponding language switching. Simple and easy to operate.

Product name: Thick-walled steel pipe annealing equipment

Workpiece materials: Q195, Q235, 10, 20, 35, 45, 304, 316, 20Cr, 40Cr, 20CrMo, 35CrMo, 42CrMo, 40CrNIMO, GCr15, 65 Mn, 50Mn, 50Cr, 3Cr2W8V, 20CrMnTi, 5CrMnMo, etc.

Workpiece diameter range: 20mm~500mm in diameter

Workpiece length range: more than 2m

Intelligent intermediate frequency power supply series: KGPS160KW-8000kW

Power consumption: Calculated according to the customer’s workpiece material and diameter, heating temperature, operating speed, etc.

Conveying roller table of thick-walled steel pipe annealing equipment: The axis of the roller table and the axis of the workpiece form an angle of 18-21°, and the workpiece moves forward at a uniform speed while autotransmitting, so that the heating is more uniform. The roller table between the furnace body is made of 304 stainless steel and water-cooled, and the thick-wall steel pipe annealing equipment has no radiation to the human body. The operation is simple and can be learned in a few minutes.