- 30

- Dec

Introduction to the composition of fused mullite

Introduction to the composition of fused mullite

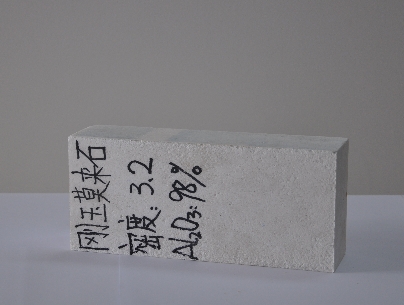

Fused mullite products usually use high alumina bauxite, iron bauxite, industrial alumina and refractory clay as raw materials. The correct selection of ingredients is an important process condition for preparing fused bricks with high mullite content and low corundum and glass phases. The aluminum oxygen coefficient of the ingredients represents the relative content of Al2O3 and SiO2 in the ingredients, and indirectly reflects the amount of mullite produced in the fused brick. Add a small amount of reducing agent (charcoal or fine-grained coke) to the ingredients. In order to make the gas generated during the melting process easy to escape, a small amount of wood chips should be added to the ingredients, and the melting should be carried out at a temperature of 900-2200°C.