- 26

- Jan

Kobberrør induksjonsoppvarming kontinuerlig annealing produksjonslinje

Kobberrør induksjonsoppvarming kontinuerlig annealing produksjonslinje

I. Complete machine structure

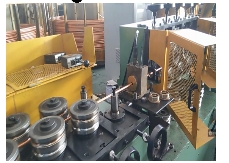

Continuous on-line return furnace consists of feeding discharge mechanism, clip host, heating frequency furnace, insulation furnace, quenching and blow drying mechanism, sioning mechanism, material collection mechanism and speed measurement device of auxiliary system, and computer control core system.In the continuous online annealing unit, the induction heating furnace is the core of the normal operation of the whole machine, and the computer automatic control system is the control core.

Process flow of continuous annealing production line of copper tube induction heating

Process flow: feeding basket in place-copper pipe through the well cover test roller to the front feeding mechanism-cleaning the outer wall-blow drying-horizontal straightening-vertical straightening-vertical feeding-induction heat-insulation-quenching cooling-blow drying-clip tensioning mechanism-material collection

II. Structure and characteristics of the control system system

The continuous annealing of copper wire induction heating production line is fully automatic operation. After completing the lead pipe work, the operator only needs to set the annealing wire speed and annealing temperature online, and all other operations are automatically realized by the computer.The control system structure of the TL400 is shown in Fig.

Kontrollsystemet har følgende egenskaper:

(1) The driving system for the receiving and discharging mechanism and the clip and correction mechanism adopts a series of vector controller, and the driving system for the tension mechanism adopts a DC controller.

(2) The computer system adopts Taiwan research and China.Operating system xp can achieve networked control.

(3) The human-computer interface adopts Samsung 23-inch LED screen touch screen is very convenient for operation and debugging personnel for system monitoring.

(5) Application software In addition to the conventional logic control, the tube induction continuous annealing controller application software has the following functions:

① P-V (power-one speed) automatic follow function.Medium frequency power supply according to pipe specification and annealing process requirements

The output power automatically follows the speed change of the aluminum tube to ensure the stable annealing temperature.The TL400 aluminum tube speed can be continuously adjustable at 201,400m / min.

The ② uses the measured module to calculate the control voltage of the medium frequency power supply.The method is simple and reliable and not subject to temperature device

Influence of the operating status of the power measuring system.The precise power control model ensures the control accuracy of the annealing furnace.

Microtension control function of the ③ aluminum tube.The aluminum tube is automatically built during the heating process, so that the aluminum tube is annealed

Not stretched or stacked in the state.

④ charge and material charge speed compensation function.Use live sleeve test and collection and discharge speed compensation calculation to ensure the collection of material basket

The discharge speed follows the line speed of the annealed aluminum tube, and the discharge material is stable and balanced.

III. Main technical parameters of the equipment

| ordrenummer | navn | spesifikasjoner | bemerkninger | ||

| 1 | Oppvarmingsmateriale | Kobber | |||

| 2 | External diameter of annealing pipe material | Φ6.0–22.0 mm | |||

| 3 | Maksimal veggtykkelse | 0.3-2.0mm | |||

| 4 | The annealing speed | 30 ~ 400m / min | |||

| 5 | Total power of the medium-frequency power supply | 400KW | |||

| 6 | High annealing temperature of pipe material Z | 550 ℃ | |||

| 7 | Normal annealing temperature of the pipe material | 400-450 ℃ | |||

| 8 | Material basket specifications | Φ3050 × 1500 mm | |||

| 9 | Maksimal materialvekt | 600kg | |||

| 10 | Maximum collection and roll drive capability: | 2,000 k g (aluminum pipe + material basket) | |||

| 11 | Quality standards for aluminum pipe after annealing: | Compliance with the current S standards | |||

| 12 | Recover and discharge roller | Two jobs | |||

| 13 | Control the total power supply | 90 kW | |||

| 14 | Total installert effekt på enheten | 900kw | |||

| 15 | gross weight of equipment | 30T | |||

| 16 | Hydraulisk systemtrykk | 100 kgf / cm2 | |||

| 17 | Hydraulisk systemflyt | 10L / min | |||

| 18 | Compress air pressure | 4-7 kgf / cm2 | |||

| 19 | Compressed gas dosage | 120-200Nm3 / h | |||

| 20 | Nitrogentrykk | 3-5 kgf / cm2 | |||

| 21 | Nitrogenstrøm | 60-80Nm3 / h | |||

| 22 | Power supply closed-loop cooling tower | ||||

| 23 | Open ring cooling tower | ||||

| 24 | gulvplass | Unit width is 12,620 m m

Unit center is 1100mm high The total length of the unit is 27,050 m m Total height of the unit is 2,200 m m The center of material collection and discharge is 24,000 m m away |

|||

| 25 | Total installed capacity (1,000 k W) | ||||

| furnace profile | Total power of the medium-frequency power supply | Total motoreffekt | Kontroller kraft | gross capacity | |

| TL 400/×400 | 2 × 400 | 80 | 10 | 900 | |

Main technical specifications of LTL400450 aluminum pipe induction continuous annealing device (simply annealing furnace) are as follows:

| Spesifikasjonskode | TL400/2×450 |

| Maksimal glødehastighet (m/min) | 400 |

| Nominal nominal power (kW) | 400KW |

| Maximum outer diameter (mm) | 28.0 |

| Minimum outer diameter (mm) | 7.0 |

| Maximum annealing temperature (℃) | 550 |

| Normal annealing temperature of pipe material (℃) | 450 |